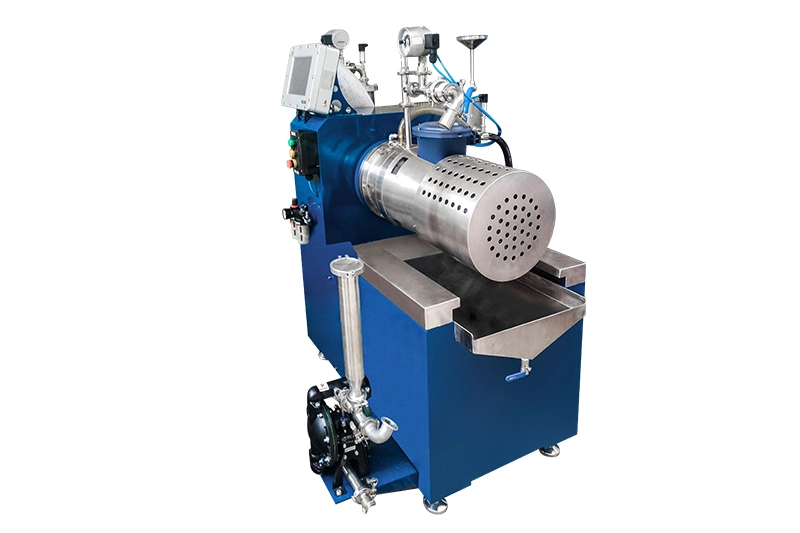

LMM Ultra-fine Centrifugal Nano Bead Mill 3L

The centrifugal discharge method ensures uninterrupted operation of the equipment without material blockage, allowing for the use of smaller grinding media and achieving finer grinding results.

Product Display

Product Description

The ultra-fine centrifugal nano bead mill can be equipped with either Boyee's TurboMax turbo or rod pin grinding system. The minimum size of the grinding media is as small as 0.05mm. The grinding and material separation processes operate independently, ensuring no material blockage and achieving even finer grinding results.

Product Advantages

● Dual power material grinding and separation operate independently

● The centrifugal separation ensures stable operation without material blockage.

● Suitable for low viscosity materials

● Finer grinding and dispersion effect

● Optional turbo and rod pin grinding systems

Product Parameters

| Model | Volume(L) | Power(kW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| LMM-3L | 3 | 7.5 | 0-1450 | 0.1-1 | 800 | 1400×1100×1680 |

| LMM-10L | 10 | 18.5 | 0-1460 | 0.05-1 | 1500 | 1800×1200×1550 |

| LMM-30L | 30 | 45 | 0-1000 | 0.05-1 | 2100 | 1800×1300×1800 |

| LMM-60L | 58 | 75 | 0-776 | 0.05-1 | 2800 | 3290×1478×1950 |

| LMM-90L | 98 | 75-90 | 0-776 | 0.05-1 | 3377 | 3290×1478×1950 |

| LMM-150L | 120-180 | 160 | 0-627 | 0.05-1 | 5600 | 4500×1700×2400 |

| LMM-400L | 400 | 315 | 0-927 | 0.05-1 | 8600 | 4600×1600×2400 |

Product Features

The centrifugal discharge method ensures uninterrupted operation of the equipment without material blockage, allowing for the use of smaller grinding media and achieving finer grinding results.

Product Application

Faqs

Mechanical seals are an important component in bead mills and other machinery used for materials processing. Here are some common problems that can occur with mechanical seals and their solutions:

Leakage: This is one of the most common problems with mechanical seals. It can be caused by a variety of factors, including improper installation, wear and tear, or damage to the seal itself. To solve this problem, check the seal's installation, replace damaged parts, and ensure that the seal is properly lubricated.

Poor Lubrication: If the mechanical seal is not properly lubricated, it can cause damage to the seal and other components. This can lead to leakage and other issues. To solve this problem, ensure that the seal is properly lubricated and use high-quality lubricants. By addressing these common problems and following proper maintenance and installation procedures, you can help ensure the longevity and reliable operation of mechanical seals in bead mills and other machinery.

Overheating: Overheating of the mechanical seal can occur due to dry running or insufficient cooling. To solve this problem, ensure the pump is adequately cooled, and the seal is lubricated properly.

Excessive vibration: Excessive vibration can lead to mechanical seal failure, and it can be caused by an unbalanced rotor, a bent shaft, or a loose motor base. The solution is to balance the rotor, replace the bent shaft, or tighten the motor base.

Wear: Mechanical seals can wear over time due to continuous use and exposure to abrasive materials. The solution is to replace the worn-out components, lubricate the seal properly, and ensure proper alignment of the seal faces.

Cavitation: Cavitation can occur when there is a sudden drop in pressure, causing the formation of bubbles that can damage the seal face. To prevent this, ensure the pump is properly primed and the inlet pressure is adequate.

Corrosion: Corrosion can occur due to exposure to corrosive materials, and it can cause the mechanical seal to fail prematurely. To prevent this, ensure the seal material is compatible with the fluid being pumped, and the seal is properly lubricated and installed.

Improper installation: Improper installation of the mechanical seal can lead to premature failure. To prevent this, ensure the seal is installed according to the manufacturer's instructions and with the proper tools.

Saturday: 9:00AM~4:00 PM