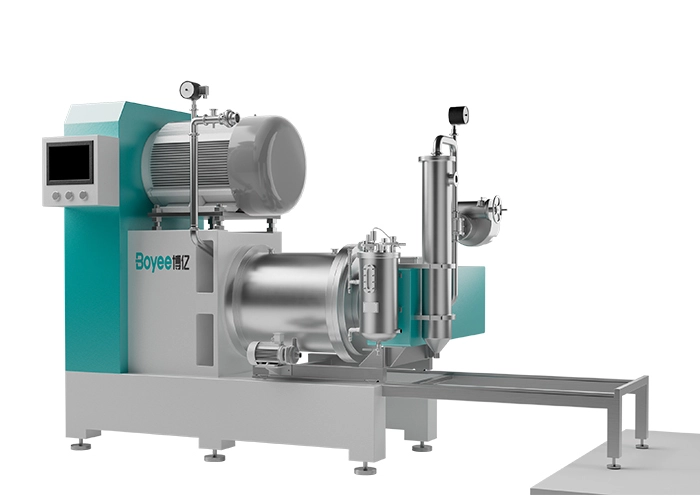

LMM Bead Mill Machine Ultra-fine Centrifugal Nano Bead Mill 400L

Centrifugal discharge mode, continuous operation of the equipment will not be blocked, excellent cooling performance, reduce equipment loss, high capacity Boyee TurboMax turbo and rod pin grinding system, can improve the production efficiency of enterprises.

Product Display

Product Description

Designed for the grinding and dispersion of low-viscosity materials, the material grinding and separation operate independently, the grinding is more fine, and the production capacity is 3 times that of ordinary bead mills.

Product Advantages

● Innovative centrifugal discharge system

● Independent operation of material grinding and separation.

● The minimum size of the grinding media can reach as low as 0.05mm.

● Optional turbo and rod pin grinding systems

● Suitable for low viscosity materials

Product Parameters

| Model | Volume(L) | Power(kW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| LMM-3L | 3 | 7.5 | 0-1450 | 0.1-1 | 800 | 1400×1100×1680 |

| LMM-10L | 10 | 18.5 | 0-1460 | 0.05-1 | 1500 | 1800×1200×1550 |

| LMM-30L | 30 | 45 | 0-1000 | 0.05-1 | 2100 | 1800×1300×1800 |

| LMM-60L | 58 | 75 | 0-776 | 0.05-1 | 2800 | 3290×1478×1950 |

| LMM-90L | 98 | 75-90 | 0-776 | 0.05-1 | 3377 | 3290×1478×1950 |

| LMM-150L | 120-180 | 160 | 0-627 | 0.05-1 | 5600 | 4500×1700×2400 |

| LMM-400L | 400 | 315 | 0-927 | 0.05-1 | 8600 | 4600×1600×2400 |

Product Features

Centrifugal discharge mode, continuous operation of the equipment will not be blocked, excellent cooling performance, reduce equipment loss, high capacity Boyee TurboMax turbo and rod pin grinding system, can improve the production efficiency of enterprises.

Product Application

Faqs

The terms "single power" and "dual power" can refer to different aspects of a bead mill, so it's important to clarify the context in which these terms are being used. However, in general, these terms may refer to the number of motors or power sources used to operate the mill.

A single power bead mill typically uses a single motor or power source to drive the milling chamber and other components of the mill. This can simplify the design and operation of the mill, and may be sufficient for many applications.

In contrast, a dual power bead mill may use two motors or power sources to drive the milling chamber and other components. This can provide greater control over the grinding process, and may be necessary for more demanding or specialized applications.

One example of a dual power bead mill is a mill that uses a separate motor or power source to drive the agitator and the pump, which are responsible for moving the beads and the material being processed through the mill. This can help to ensure a more consistent and efficient grinding process, and may be particularly useful for applications that require very fine or uniform particle size distributions.

Overall, the choice between a single power and dual power bead mill will depend on the specific requirements of the application, as well as factors such as the type of material being processed, the desired particle size distribution, and the available resources and infrastructure for powering and operating the mill.

Another factor to consider when choosing between a single power and dual power bead mill is the level of control over the grinding process that is needed. In general, a dual power bead mill may offer greater control over the speed, flow rate, and other parameters of the grinding process, which can be important for achieving a specific particle size distribution or other desired properties in the final product.

For example, a dual power bead mill may allow the speed of the agitator and the flow rate of the material to be adjusted independently, which can help to optimize the grinding process for a particular material or application. This level of control may not be possible with a single power bead mill, which may have more limited adjustment options.

On the other hand, a single power bead mill may be simpler and more straightforward to operate, which can be an advantage for applications where simplicity and ease of use are more important than fine-tuned control over the grinding process.

Another important consideration when choosing between a single power and dual power bead mill is the capacity of the machine. Generally, dual power bead mills are larger and have higher capacity than single power bead mills, due to the need for additional motors and control systems.

The capacity of a bead mill is typically measured in terms of the volume of material that can be processed per unit time. This can be influenced by a range of factors, including the size and design of the grinding chamber, the speed and power of the agitator, and the size and density of the grinding media.

In general, a larger and more powerful bead mill will be able to process larger volumes of material more quickly and efficiently. However, this may also come with a higher cost and greater complexity in terms of operation and maintenance.

Ultimately, the choice between a single power and dual power bead mill will depend on a range of factors, including the specific requirements of the application, the available resources and infrastructure, and the budget and timeframe for the project.

Saturday: 9:00AM~4:00 PM