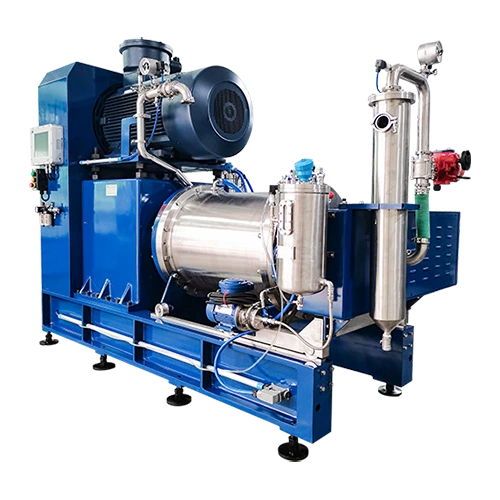

LMM Ultra-fine Centrifugal Nano Bead Mill 60L

The ultra-fine centrifugal nano bead mill features a highly efficient grinding system equipped with either a rod pin or turbo-style structure. It achieves a finer grinding fineness and allows for the independent operation of material grinding and separation, freeing you from the troubles of screen clogging.

Product Display

Product Description

The centrifugal discharge method enables continuous operation of the equipment without any material blockages, resulting in improved production efficiency and grinding fineness. It is suitable for low viscosity materials and offers the option of choosing between turbo-style and rod pin grinding systems.

Product Advantages

● Innovative centrifugal system design

● Material grinding and separation operate independently

● The minimum size of the grinding media can reach as low as 0.05mm.

● Optional turbo and rod pin grinding systems

● A wide range of options for grinding chamber and structural component materials are available to meet your specific requirements.

Product Parameters

| Model | Volume(L) | Power(kW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| LMM-3L | 3 | 7.5 | 0-1450 | 0.1-1 | 800 | 1400×1100×1680 |

| LMM-10L | 10 | 18.5 | 0-1460 | 0.05-1 | 1500 | 1800×1200×1550 |

| LMM-30L | 30 | 45 | 0-1000 | 0.05-1 | 2100 | 1800×1300×1800 |

| LMM-60L | 58 | 75 | 0-776 | 0.05-1 | 2800 | 3290×1478×1950 |

| LMM-90L | 98 | 75-90 | 0-776 | 0.05-1 | 3377 | 3290×1478×1950 |

| LMM-150L | 120-180 | 160 | 0-627 | 0.05-1 | 5600 | 4500×1700×2400 |

| LMM-400L | 400 | 315 | 0-927 | 0.05-1 | 8600 | 4600×1600×2400 |

Product Features

The ultra-fine centrifugal nano bead mill features a highly efficient grinding system equipped with either a rod pin or turbo-style structure. It achieves a finer grinding fineness and allows for the independent operation of material grinding and separation, freeing you from the troubles of screen clogging.

Product Application

Faqs

The cooling system of a bead mill is an important feature that helps to maintain a consistent temperature during the milling process. Here are some details about the cooling system:

Bead mills generate a significant amount of heat during operation, which can affect the quality of the product and the performance of the equipment. Therefore, a cooling system is necessary to regulate the temperature of the mill and prevent overheating.

The cooling system typically consists of a cooling jacket or chamber that surrounds the milling chamber and a coolant, such as water or a glycol solution, that circulates through the jacket to absorb heat.

Some bead mills have a built-in cooling system, while others may require an external chiller or cooling tower to provide the necessary cooling.

The temperature of the coolant can be controlled using a thermostat or temperature controller, which adjusts the flow rate of the coolant to maintain a set temperature.

The efficiency of the cooling system can be affected by several factors, including the flow rate of the coolant, the temperature of the coolant, and the design of the cooling jacket.

Proper maintenance of the cooling system is important to ensure that the equipment operates at optimal performance. This includes regularly cleaning and flushing the cooling system to prevent buildup of contaminants or scale, and replacing worn or damaged parts as needed.

The cooling system of a bead mill is an important part of the machine that helps to maintain a stable temperature during the milling process. The cooling system prevents overheating of the grinding chamber, which can affect the quality of the final product.

There are different types of cooling systems that can be used in a bead mill. The most common ones are water-cooling and air-cooling systems. Water-cooling systems are generally more effective at dissipating heat, but they require a constant supply of water, which can be a challenge in some environments. Air-cooling systems are simpler and more energy-efficient, but they may not be sufficient for high-intensity milling operations.

The effectiveness of the cooling system depends on several factors, such as the type of coolant used, the flow rate of the coolant, the temperature of the coolant, and the size and design of the cooling channels. It is important to choose a cooling system that is appropriate for the specific milling application and to monitor the temperature of the grinding chamber regularly to ensure that it stays within the desired range.

Some bead mills may also be equipped with a temperature control system that allows the operator to adjust the temperature of the coolant based on the requirements of the milling process. This can help to optimize the efficiency and quality of the milling operation.

Saturday: 9:00AM~4:00 PM