OEM Nano Grinding Mill BOYEE 37-45

Product Display

Product Description

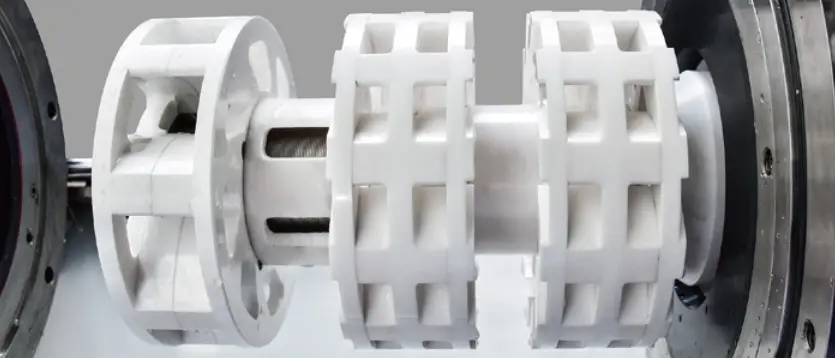

The BYZr model can be equipped with Boyee independently developed PurCeram all-ceramic technology and TurboMax turbo grinding structure. This combination reduces material contamination and enables continuous circulation grinding.

Product Advantages

● Unique discharge method minimizes the occurrence of screen clogging.

● All-ceramic structure ensures no contamination of materials, resulting in a purer and finer grinding process.

● Flexible grinding, no damage to material morphology

● Suitable for higher viscosity materials

● Unique cooling system design

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Media diameter (mm) | Weight (kg) | Size (mm) |

| BYZr-3L | 2.2 | 7.5 | 0-1450 | 0.3-1 | 468 | 1200×1050×1450 |

| BYZr-15L | 11 | 30 | 0-1860 | 0.3-1 | 1205 | 1600×1350×1850 |

| BYZr-30L | 22 | 37-45 | 0-1325 | 0.3-1.2 | 1425 | 1750×1350×1850 |

Product Features

The first independently developed all-ceramic nano bead mill in China, which innovative mill features a fully ceramic structure from the rotor to the grinding chamber, which minimizes material contamination, ensures material purity, and extends the equipment's lifespan.

Product Application

Faqs

Bead mills are commonly used in the production process of lithium iron phosphate (LiFePO4) due to their ability to finely grind and disperse the components of the battery material. In the production of LiFePO4, the bead mill is used to grind the raw materials, including lithium iron phosphate, conductive carbon, and a binder, into a fine powder with a particle size of around 1-5 microns. The finely ground powder is then mixed with a solvent to form a slurry, which can be coated onto a current collector to form the cathode of the battery.

The use of a bead mill in the production of LiFePO4 is essential for achieving a high-quality and uniform battery material. The high shear forces generated by the grinding beads help to break up any agglomerates in the raw materials, resulting in a more uniform particle size distribution and improved electrochemical performance of the battery.

Company Advantages

· BOYEE nano grinding mill grows more varied with time and technology.

· The product is highly preferred by our clients for its competitive advantages of high quality, stable performance, strong practicality.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD has established a globally independent brand with superior products and services.

Company Features

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is well equipped to manufacture quality nano grinding mill.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD use the potential of our high-quality employees to continuously improve our nano grinding mill.

· BOYEE aims to create BOYEE as the first brand of nano grinding mill industry. Please contact us!

Application of the Product

The nano grinding mill produced by BOYEE has a wide range of applications.

BOYEE insists on providing customers with one-stop and complete solution from the customer's perspective.

Saturday: 9:00AM~4:00 PM