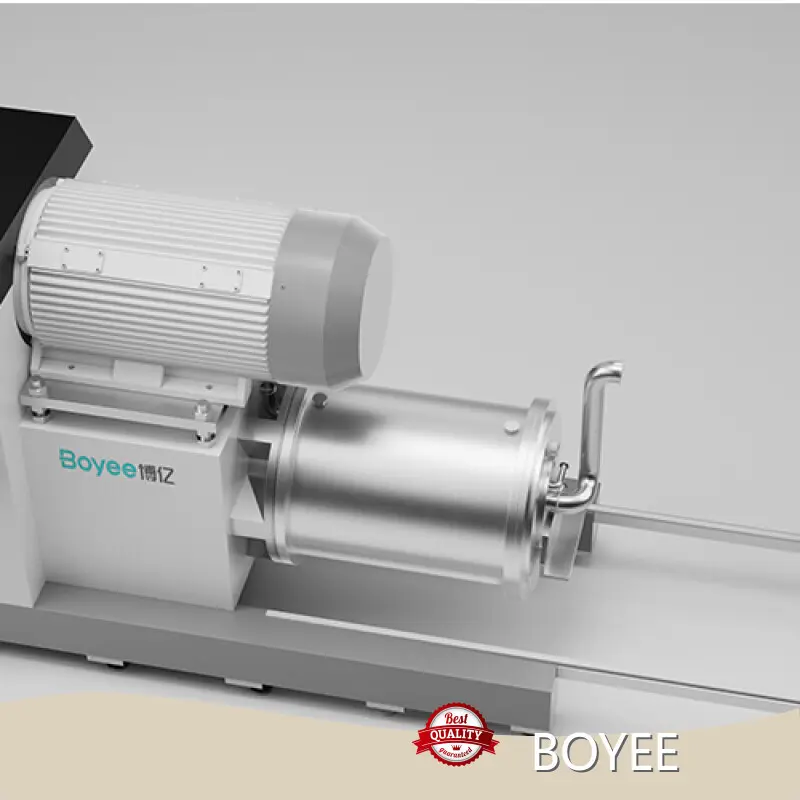

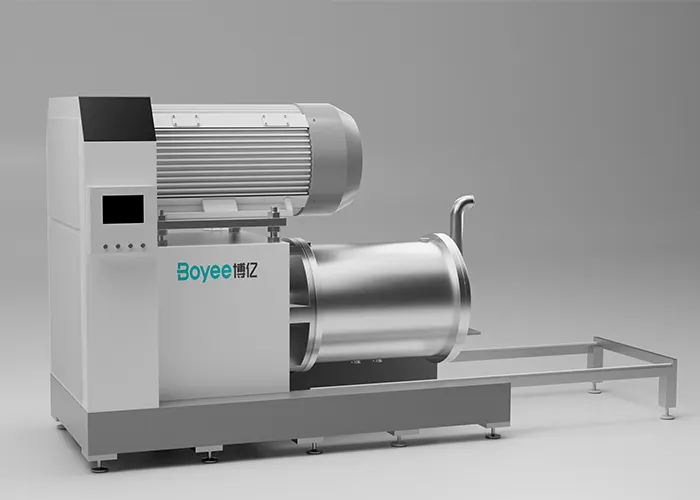

Latest Lab Sand Mill NMM60L Factory

Product Display

Product Description

Boyee's patented TurboMax turbo and rod pin grinding systems effectively enhance grinding quality and precision, reduce cost of losses, and improve production efficiency.

Product Advantages

● Exceptional capability in handling high viscosity materials.

● Widely used in a variety of materials on the market

● Smooth material discharge without any blockages.

● Optional Boyee TurboMax patented turbo and rod pin grinding systems

● Ceramic, polymer and alloy components are available

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Mediadiameter (mm) | Weight (kg) | Size (mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | ≥0.2 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

Product Features

Boyee's patented TurboMax turbo and rod pin grinding systems effectively enhance grinding quality and precision, reduce cost of losses, and improve production efficiency.

Product Application

Faqs

Choosing the right size and weight of zirconium beads for your bead mill will depend on several factors, including the material being milled, the desired particle size distribution, and the milling conditions. Here are some general guidelines:

Material being milled: The hardness and density of the material being milled can impact the size and weight of the beads needed. Harder and denser materials may require larger and heavier beads to effectively break down the particles.

Desired particle size: The size of the beads will impact the final particle size distribution. Smaller beads can result in finer particle size distributions, while larger beads may produce coarser particles.

Milling conditions: The speed and intensity of the milling process can also impact the size and weight of the beads needed. Higher milling speeds or longer milling times may require larger and heavier beads to maintain the desired milling intensity.

Bead-to-material ratio: The ratio of beads to material in the milling chamber can also impact the size and weight of the beads needed. Higher bead-to-material ratios may require larger and heavier beads to maintain efficient milling.

Equipment limitations: The size and weight of the beads should also be compatible with the equipment being used. Check the manufacturer's recommendations for the maximum size and weight of beads that can be used in your specific bead mill.

Chemical compatibility: Zirconium beads are highly resistant to corrosion, but it's still important to ensure that the beads are chemically compatible with the material being milled. Some materials may react with the zirconium, which can result in contamination of the final product.

Bead shape: In addition to size and weight, the shape of the beads can also impact the milling process. Cylindrical or spherical beads are the most common shapes, but there are also conical, tri-lobed, and other specialized shapes available. The shape of the beads can impact the flow dynamics within the milling chamber, which can affect the efficiency of the milling process.

Bead quality: The quality of the beads can also impact the milling process and the final product. Look for beads that are uniform in size and shape, and free from defects or irregularities.

Cost: The cost of the beads can vary depending on the size, weight, and quality. Consider the cost of the beads relative to the cost of the material being milled, as well as the potential impact on the final product.

In general, zirconium beads are available in a range of sizes from 0.1 mm to several millimeters in diameter, and weights can vary depending on the specific bead size and material composition. Consult with the bead manufacturer or supplier for specific recommendations based on your application and equipment.

Company Advantages

· BOYEE lab sand mill is engineered with the assistance of our professionals.

· Strict and perfect quality control system makes lab sand mill's quality more stable.

· After years of experience in producing lab sand mill, BOYEE is skilled in this field.

Company Features

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is specialized in research, production and sales of lab sand mill.

· It is professional R&D base that makes lab sand mill improved greatly.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is highly reliable among customers at home and abroad for our superior lab sand mill. Inquiry!

Application of the Product

BOYEE's lab sand mill can be used in different industries to meet the needs of customers.

According to different needs of customers, BOYEE is capable of providing reasonable, comprehensive and the most cost-effective solutions for customers.

Saturday: 9:00AM~4:00 PM