Intelligentproduction line solutionsfor lithium-ion batterycathode materials

1,BOYEE possesses ample design experience in one-stop smart factory solutions, empowering you to streamline and optimize your production processes.

2,Precise metering and dosing, efficient pulp mixing, and advanced dispersion and grinding systems enhance the consistency in the quality of manufactured products.

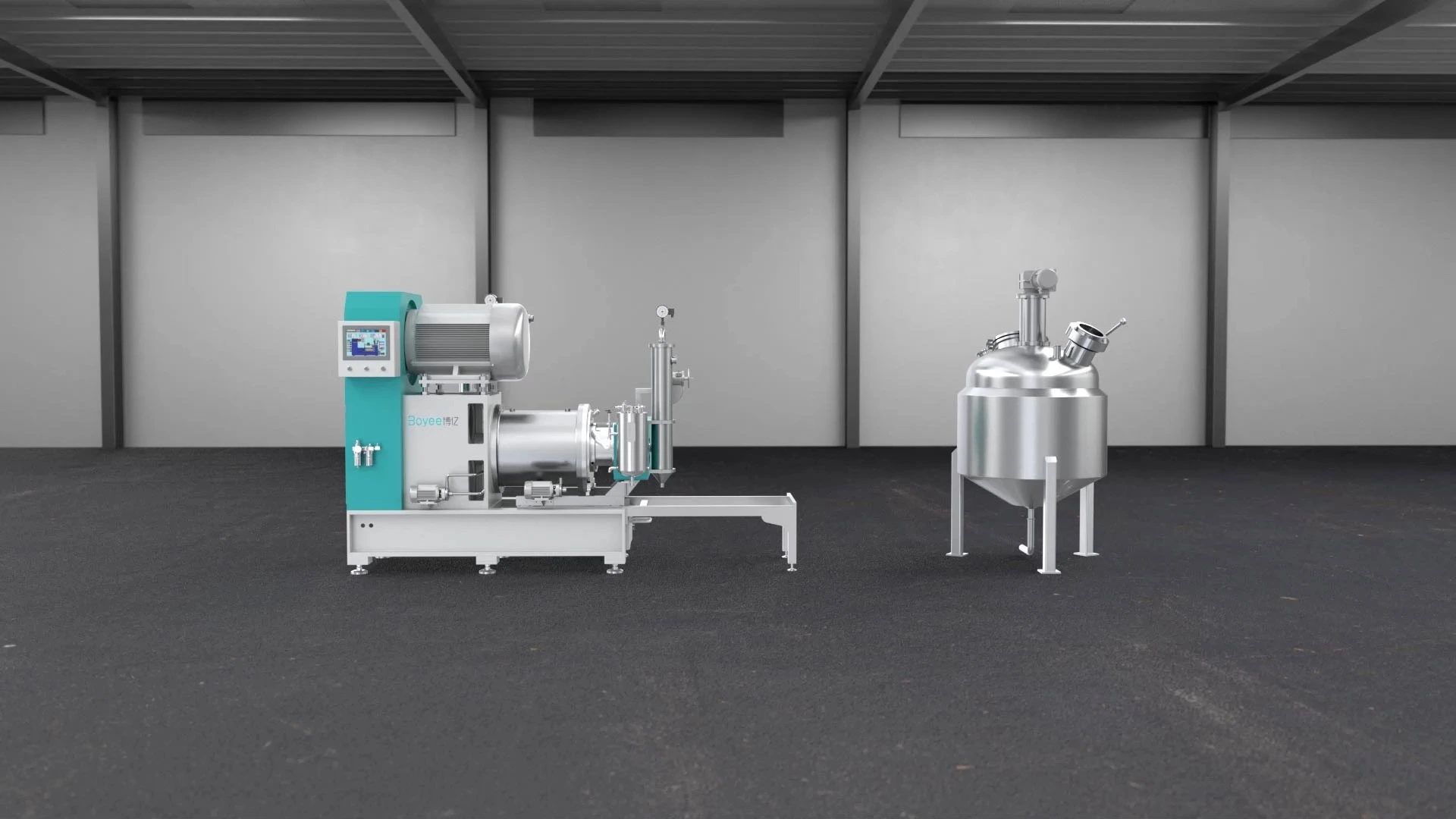

Product Display

Product Description

This equipment is suitable for grinding in higher education institutions, research institutions, and corporate laboratories. It can be used for grinding new materials and various process experimentation requirements. It is an ideal choice for product development and small-scale production.

Product Advantages

● Ideal for developing process technologies in higher education institutions, research institutions, and corporate laboratories.

● Integrated machine design, convenient disassembly, simple operation

● The experimental data can be scaled up for production

● The minimum grinding medium is 0.1mm

● Suitable for small scale grinding and production

Product Parameters

| Model | Volume(L) | Power(KW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| NMM-1L | 1 | 2.2 | 0-2960 | 0.1-1 | 150 | 1000×580×1750 |

| NMM-2L | 2 | 4.5 | 0-2960 | 0.1-1 | 260 | 1200x800x1800 |

Product Features

The Boyee NMM multifunctional laboratory machine is designed for small-scale testing and formulation development in laboratory-scale processes.

Product Application

Faqs

Here are some matters that need attention when using the bead mill:

Safety: Safety should be a top priority when operating the bead mill. Users should be trained in the safe operation of the mill, wear appropriate personal protective equipment (PPE), and follow all safety guidelines and protocols.

Material preparation: Proper material preparation is critical for the effective operation of the bead mill. Materials should be properly pre-dispersed and filtered to remove any impurities or contaminants that may clog the mill or affect the quality of the final product.

Bead selection: Choosing the right type and size of grinding beads is critical for achieving the desired particle size and dispersion quality. Users should consult with the bead mill manufacturer or supplier to determine the appropriate bead material and size for their specific application.

Bead filling: Proper bead filling is critical for achieving optimal milling conditions and preventing excessive wear on the mill components. Users should follow the manufacturer's recommended bead filling guidelines and adjust as necessary based on the specific application.

Cooling: Effective cooling is critical for preventing overheating of the mill and ensuring consistent product quality. Users should monitor the temperature of the mill and adjust the cooling system as necessary to maintain optimal operating conditions.

Cleaning and maintenance: Proper cleaning and maintenance of the bead mill are critical for ensuring consistent performance and extending the life of the mill components. Users should follow the manufacturer's recommended cleaning and maintenance procedures and perform routine inspections and repairs as needed.

By paying close attention to these critical factors and following proper operating procedures, users can achieve optimal performance and extend the life of their bead mill.

Operating parameters: Users should pay close attention to the operating parameters of the bead mill, including milling speed, flow rate, and residence time. These parameters can have a significant impact on the efficiency and quality of the milling process and should be adjusted as necessary to optimize performance.

Particle size analysis: Regular particle size analysis is critical for monitoring the quality and consistency of the milling process. Users should perform regular particle size analysis and adjust the milling parameters as necessary to achieve the desired particle size and distribution.

Sample size: The amount of material being processed in the bead mill can have a significant impact on the efficiency and performance of the milling process. Users should consult with the bead mill manufacturer or supplier to determine the appropriate sample size for their specific application.

Process validation: Validating the bead milling process is critical for ensuring consistent quality and reproducibility of the final product. Users should perform regular process validation to verify that the milling process is achieving the desired results and make any necessary adjustments.

Product compatibility: Certain materials may not be compatible with certain types of grinding media or may require specialized equipment to prevent contamination or degradation. Users should consult with the bead mill manufacturer or supplier to determine the appropriate equipment and media for their specific application.

Material viscosity: The viscosity of the material being processed can have a significant impact on the efficiency and performance of the bead mill. Users should adjust the milling parameters and select appropriate grinding media based on the viscosity of the material being processed.

Agitation: Proper agitation is critical for achieving optimal milling conditions and preventing settling or sedimentation of the material. Users should monitor the agitation of the material and adjust the milling parameters as necessary to maintain consistent conditions.

Discharge: Proper discharge of the milled material is critical for preventing contamination or degradation of the final product. Users should ensure that the discharge process is properly designed and that the equipment is properly cleaned and maintained.

Environmental considerations: The bead milling process can generate dust, noise, and other environmental concerns. Users should follow all applicable environmental regulations and guidelines and take appropriate measures to minimize the impact of the milling process on the environment.

Safety: The bead mill can present safety hazards such as electrical hazards, entanglement hazards, or exposure to hazardous materials. Users should follow all safety procedures and guidelines and ensure that they are properly trained in the safe operation of the equipment.

Maintenance: Regular maintenance is essential for ensuring the optimal performance and longevity of the bead mill. Users should follow the manufacturer's recommended maintenance procedures and schedules and keep a record of all ma

Saturday: 9:00AM~4:00 PM