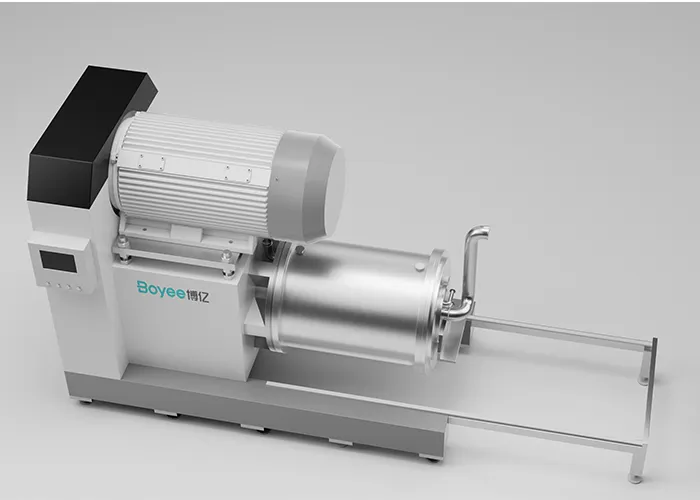

Horizontal Sand Mill Factory 3050

Company Advantages

· BOYEE horizontal sand mill is manufactured in accordance with the quality standards of the industry.

· This product is thoroughly checked and is able to endure long-term usage.

· The product can create a large profit margin for customers.

Product Display

Product Description

The screen-type bead mill, which is favored for handling high-viscosity materials, overcomes the traditional clogging problem. It is equipped with Boyee's independently developed TurboMax turbine structure, providing excellent operational stability, higher equipment flow, improved production efficiency, and reduced costs.

Product Advantages

● Higher flow

● High-quality handling capability for high-viscosity materials.

● Optional TurboMax turbine and rod pin grinding system.

● Optional ceramic, polymer, and alloy material components.

● Longer screen lifespan.

● All models meet the requirements from laboratory to large-scale production.

● Daily maintenance is simple and quick.

● Low noise impact.

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Mediadiameter (mm) | Weight (kg) | Size (mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | ≥0.2 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

Product Features

Boyee TurboMax patented turbine and rod-pin grinding system can deliver energy to the grinding medium before achieving nano-level grinding and dispersion effects.

Product Application

Faqs

In a bead mill, the terms "dynamic discharge" and "static discharge" refer to two different methods of discharging the ground material from the mill.

Dynamic discharge, also known as pump or forced discharge, involves using a pump to force the material out of the mill through a discharge valve. This method is typically used with higher viscosity materials or materials that tend to stick to the walls of the mill, as it can help ensure a more complete discharge of the material and prevent clogging.

Static discharge, on the other hand, relies on gravity to discharge the material from the mill. In this method, the mill is tilted or inclined at an angle, allowing the ground material to flow out through a discharge port located at the bottom of the mill. This method is typically used with lower viscosity materials or materials that are less likely to stick to the walls of the mill, as it may not be as effective at ensuring a complete discharge of the material.

Overall, the choice of discharge method depends on the specific characteristics of the material being processed and the requirements of the application. Both dynamic and static discharge can be effective for different types of materials and applications, and it's important to choose the method that will provide the best results for your specific situation.

One important factor to consider when choosing between dynamic and static discharge is the viscosity of the material. Materials with higher viscosity may require dynamic discharge to ensure a more complete discharge of the material and prevent clogging. However, dynamic discharge may not be as effective with lower viscosity materials, which may flow more easily through a static discharge system.

Another factor to consider is the particle size of the material. Materials with larger particle sizes may require dynamic discharge to ensure that the larger particles are properly ground and discharged from the mill. Conversely, smaller particle sizes may be more effectively discharged through a static discharge system.

The specific requirements of the application may also play a role in determining the best discharge method. For example, if a continuous flow of material is required, dynamic discharge may be more appropriate. However, if batch processing is being used, static discharge may be more convenient.

Another important factor to consider when choosing between dynamic and static discharge is the nature of the material being processed. Some materials may be more prone to clogging or buildup within the mill, which can affect the efficiency of the grinding process and the effectiveness of the discharge method.

For example, materials that contain high levels of solids or other impurities may be more prone to clogging, making dynamic discharge more necessary. In contrast, materials that are more homogenous and free of impurities may be better suited for static discharge.

The specific design of the bead mill can also play a role in determining the most effective discharge method. Some bead mills may be specifically designed for dynamic discharge, while others may be better suited for static discharge.

Overall, the choice between dynamic and static discharge will depend on a variety of factors, including the nature of the material being processed, the design of the bead mill, and the specific requirements of the application. By carefully evaluating these factors and choosing the most appropriate discharge method, it's possible to optimize the performance of the bead mill and achieve the desired grinding results.

Company Features

· BOYEE seized the favorable opportunity to achieve the rapid growth in the history of horizontal sand mill industry.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD has dedicated teams of R&D, engineers and quality control experts on horizontal sand mill product development.

· Innovation is a key component of the core competitiveness of a company and the driving force for its growth.

Product Details

BOYEE pays great attention to details of horizontal sand mill.

Application of the Product

BOYEE's horizontal sand mill is widely used in multiple industries and fields.

BOYEE always pays attention to customers. According customers' actual needs, we could customize comprehensive and professional solutions for them.

Product Comparison

Compared with peer products, our company's horizontal sand mill has the following characteristics.

Enterprise Advantages

BOYEE focuses on the cultivation of scientific and technological talents. At present, a team of experienced experts and elite personnel has been established to provide a strong guarantee for product development.

BOYEE always puts customers first and treat each customer sincerely. Besides, we strive to meet the requirements of customers and solve their problems duly.

Our company always considers talents as one of the decisive factors for our sustainable development. We focus on talents management and cooperation, so a talent team is created to be the soul of our company. It is the motivation for the efficient development.

BOYEE was founded in After years' development from puniness to mightiness, we have grown into a leader in the industry .

BOYEE's Bead mill receive trust and favor from domestic and foreign customers.

Saturday: 9:00AM~4:00 PM