BOYEE Top Nano Milling Machine 1425

Company Advantages

· The source of raw materials: before BOYEE nano milling machine comes out, it is processed from high quality raw materials. These materials are sourced from several different places within and out of the region.

· Its long service life is greatly ensured by the strict testing procedure.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is able to meet the needs of different customers and new nano milling machine product development.

Product Display

Product Description

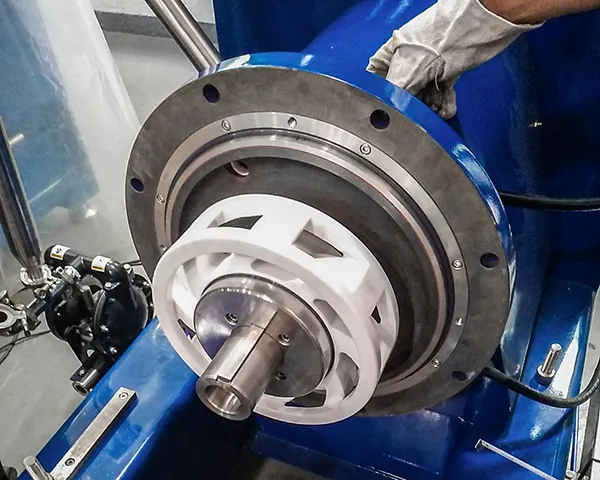

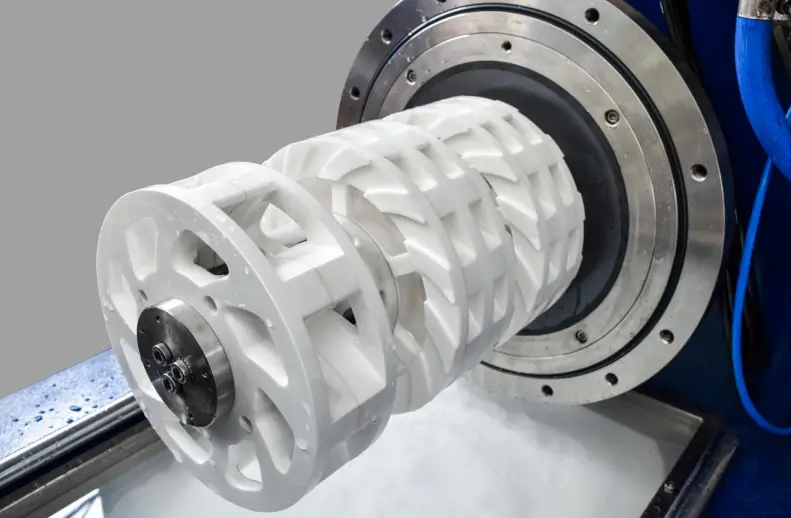

The BYZr bead mill adopts the TurboMax turbo grinding structure, which effectively prevents excessive dispersion of materials, improves the grinding media, reduces energy consumption, enhances the wear resistance of ceramic components, ensures greater equipment stability, and extends its lifespan while maintaining low maintenance costs.

Product Advantages

● Turbo type grinding structure for more refined grinding effect

● High grinding efficiency, large output and low energy consumption

● It is suitable for nano-level grinding of medium and low viscosity materials

● All ceramic accessories grinding material, reduce material pollution

● High flow flexible grinding, concentrated particle size, no damage to material morphology

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Media diameter (mm) | Weight (kg) | Size (mm) |

| BYZr-3L | 2.2 | 7.5 | 0-1450 | 0.3-1 | 468 | 1200×1050×1450 |

| BYZr-15L | 11 | 30 | 0-1860 | 0.3-1 | 1205 | 1600×1350×1850 |

| BYZr-30L | 22 | 37-45 | 0-1325 | 0.3-1.2 | 1425 | 1750×1350×1850 |

Product Features

BYZr ceramic turbo bead mill is a Chinese nano-level all-ceramic turbo bead mill independently developed by Boyee. It ensures the grinding material material zero pollution. With the built-in hollow shaft and turbo structure, it enables flexible grinding without damaging the morphology of the material, resulting in superior grinding performance.

Product Application

Faqs

The bearing is an essential component of the bead mill. Proper installation and maintenance of bearings can ensure the smooth operation of the machine. Here are some tips for bearing installation and maintenance.

Proper installation: Before installing the bearing, make sure that the bearing housing and the shaft are clean and free of any dirt or debris. Lubricate the bearing with a high-quality lubricant before installation. Also, ensure that the bearing is correctly seated in the housing and the shaft, and the fit is not too tight or too loose.

Regular maintenance: Regularly check the condition of the bearing and the lubricant. If there are any signs of wear or damage, replace the bearing immediately. Also, periodically lubricate the bearing with a high-quality lubricant to ensure smooth operation.

Temperature monitoring: Monitor the temperature of the bearing regularly. If the temperature of the bearing exceeds the recommended limit, stop the machine immediately and investigate the cause of the high temperature.

Bearing alignment: Proper alignment of the bearing is crucial for the smooth operation of the bead mill. Misalignment can cause excessive wear and tear on the bearing, leading to premature failure. Therefore, check the bearing alignment regularly and adjust it as necessary.

Cleanliness: Keep the bearing and its surrounding area clean and free of any debris or contaminants that can cause damage to the bearing.

Proper installation and maintenance of the bearing can help extend the life of the bead mill and prevent costly breakdowns.

Company Features

· As a quality-oriented enterprise, BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is seeking a wider global market for nano milling machine.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is equipped with industry-leading automated production equipment and testing equipment. BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD has introduced internationally leading and domestic first-class standardized nano milling machine production lines. BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD closely relies on scientific and technological progress, and introduces advanced equipment from overseas.

· We strive to anticipate customer needs and strive to say 'yes' to each request. We deliver exceptional quality at speeds and values that exceed expectations, leaving us with peace of mind. We strive to make all our customers win. Contact!

Product Details

With a focus on product quality, BOYEE strives for quality excellence in the production of nano milling machine.

Application of the Product

Our nano milling machine has been widely used in many industries.

We strive to provide customers with efficient, complete, and flexible solutions based on their needs.

Product Comparison

Compared with products in the same category, nano milling machine's core competencies are mainly reflected in the following aspects.

Enterprise Advantages

BOYEE has a management team and a staff team, who are both young, market-oriented and knowledgeable. The team members are equipped with strong team spirit and innovative consciousness. All of us strive to produce quality products with common efforts.

Guided by the customers, we perfect service from small things and meet their requirements for high quality products. Besides, we are doing our best to provide high quality products and high standards of service for the public.

Our company adheres to the business philosophy of 'customer first, service first', and practices the enterprise spirit of 'integrity management, hard work, and progress'. During the development, we strive to achieve standardized production, and continuously expand brand awareness. By making full use of the brand effect, we increase market share and try hard to become an industry leader.

BOYEE, established in has been engaged in the development, production, and sales of Bead mill for years.

Our product sales network covers all parts of the country, and some products are exported to some countries and regions in Asia, Europe, Latin America and Africa. So our company's social influence has been greatly improved.

Saturday: 9:00AM~4:00 PM