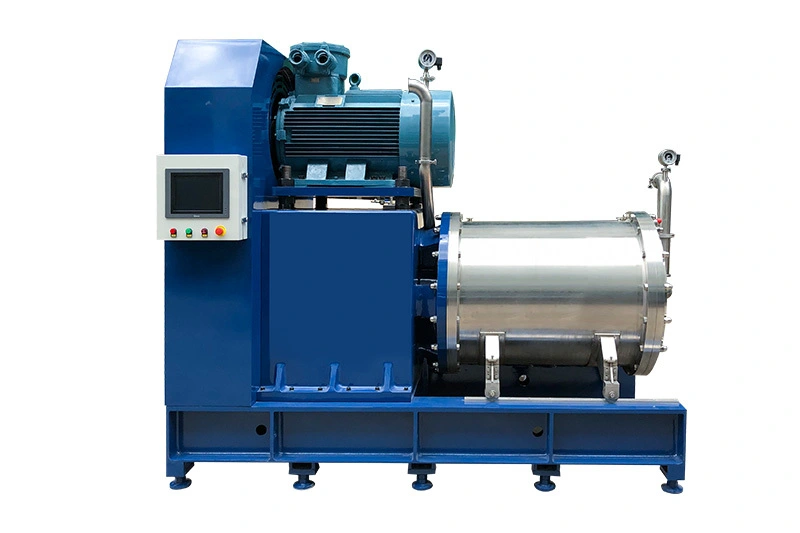

NMM Bead Mill Sand Mill Large Flow Screen Nano Bead Mill 400L

The high-flow screen-based nano bead mill offers excellent grinding performance, preventing material blockages. It enhances production efficiency for businesses and is the preferred equipment for large-scale production of numerous high viscosity materials.

Product Display

Product Description

Boyee's patented TurboMax turbo and rod pin grinding systems effectively enhance grinding quality and precision, reduce cost of losses, and improve production efficiency. They are widely applied in large-scale production of new energy materials such as nano new materials, lithium iron phosphate, carbon nanotube conductive slurry, as well as in intelligent automated production lines.

Product Advantages

● Exceptional capability in handling high viscosity materials.

● Widely used in a variety of materials on the market

● The equipment has stable performance and long service life

● Optional to Boyee TurboMax patented turbo and rod pin grinding systems

● Ceramic, polymer and alloy components are available

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Mediadiameter (mm) | Weight (kg) | Size (mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | ≥0.2 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

Product Features

The high-flow screen-based nano bead mill offers excellent grinding performance, preventing material blockages. It enhances production efficiency for businesses and is the preferred equipment for large-scale production of numerous high viscosity materials.

Product Application

Faqs

Proper maintenance is essential for ensuring the optimal performance and longevity of the bead mill. Here are some general tips for maintaining the equipment:

Follow the manufacturer's recommended maintenance procedures and schedules. The manufacturer's instructions should provide detailed guidance on maintenance procedures such as lubrication, cleaning, and inspection.

Keep the equipment clean. Regular cleaning of the equipment can help to prevent contamination and ensure that the equipment is operating at optimal performance. Clean the equipment thoroughly after each use and perform more detailed cleaning procedures on a regular basis.

Check for signs of wear and damage. Inspect the equipment regularly for signs of wear, damage, or other issues that could impact performance. Replace any damaged or worn parts as necessary.

Lubricate the equipment as recommended by the manufacturer. Proper lubrication can help to reduce wear and extend the life of the equipment. Use the recommended lubricants and follow the manufacturer's recommended procedures.

Calibrate the equipment regularly. Regular calibration of the equipment can help to ensure accurate and reliable performance. Follow the manufacturer's recommended calibration procedures and schedules.

Keep records of all maintenance activities. Maintaining detailed records of all maintenance activities can help to identify issues and prevent future problems. Keep a record of all maintenance activities, including the date, time, and nature of the activity.

Train all operators in proper maintenance procedures. Proper training is critical for ensuring that all operators are able to maintain the equipment properly. Train all operators in the manufacturer's recommended maintenance procedures and provide ongoing training as needed.

By following these general tips, users can help to ensure that their bead mill is properly maintained and operating at optimal performance.

Check the cooling system. The bead mill may generate a lot of heat during operation, and a properly functioning cooling system is essential for preventing overheating. Check the cooling system regularly and ensure that it is functioning properly.

Check the seals and gaskets. The seals and gaskets in the bead mill can wear over time, which can lead to leaks and other issues. Check the seals and gaskets regularly and replace any that show signs of wear or damage.

Keep the bead mill properly aligned. Proper alignment of the bead mill can help to prevent excessive wear and extend the life of the equipment. Check the alignment of the equipment regularly and adjust as needed.

Use high-quality beads. The quality of the beads used in the bead mill can impact the performance of the equipment. Use high-quality beads that are appropriate for the material being processed.

Perform regular inspections. Regular inspections can help to identify potential issues before they become major problems. Inspect the equipment regularly for signs of wear, damage, or other issues that could impact performance.

Store the equipment properly. When the bead mill is not in use, store it in a dry, clean, and protected area. Follow the manufacturer's recommended storage procedures.

By following these additional tips, users can help to ensure that their bead mill is properly maintained and operating at optimal performance.

Saturday: 9:00AM~4:00 PM