The Science Behind Laboratory Bead Mills: Unleashing The Power Of Nano-Sized Particles

Welcome to our comprehensive guide on the fascinating world of laboratory bead mills! In this article, we delve into the captivating realm of nano-sized particles and explore the intricate science that drives these mighty machines. Whether you're a scientist, researcher, or simply curious about cutting-edge technology, join us as we unlock the immense potential and unprecedented power of laboratory bead mills. Prepare to be mesmerized by the possibilities these innovative instruments offer and discover why they are revolutionizing the way we manipulate and unleash the true potential of nano-sized particles.

Understanding the Significance of Laboratory Bead Mills in Nano-Particle Research

In the ever-evolving world of nano-particle research, laboratory bead mills have emerged as indispensable tools for scientists and researchers. These sophisticated devices have revolutionized the way delicate particles are processed, opening up a whole new realm of possibilities in various fields of study. This article aims to shed light on the scientific principles underlying laboratory bead mills, with a particular focus on their importance and significance in nano-particle research.

The Science behind Laboratory Bead Mills:

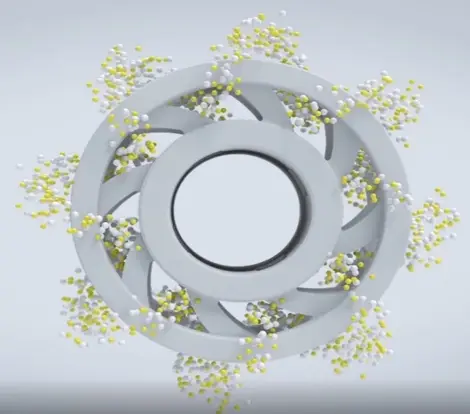

Laboratory bead mills, such as the ones manufactured by BOYEE, employ a unique mechanism to achieve efficient particle size reduction. They consist of a cylindrical chamber filled with small beads made from materials like glass, ceramic, or stainless steel. A powerful motor drives the agitator, causing the beads to collide with the particles under high-speed rotation. This intense agitation and grinding action break down larger particles into smaller, uniform sizes.

Importance in Nano-Particle Research:

1. Precise Control over Particle Size:

One of the primary reasons laboratory bead mills are invaluable in nano-particle research is their ability to precisely control particle size. The size of particles plays a crucial role in determining their properties and behavior. With laboratory bead mills, researchers can achieve uniform particle size distributions within the nano-scale range. This level of control is essential for experiments requiring specific particle sizes in areas like pharmaceuticals, materials science, and biotechnology.

2. Enhanced Surface Area and Reactivity:

Nano-particles exhibit unique properties due to their large surface area-to-volume ratio. Laboratory bead mills effectively increase the surface area of particles, leading to enhanced reactivity and improved performance. By reducing particle sizes to the nano-scale, researchers can achieve better dispersion, solubility, and dissolution rates. This, in turn, facilitates more efficient drug delivery systems, advanced catalysts, and improved materials with enhanced mechanical and electrical properties.

3. Homogenization and Dispersion of Nano-Particles:

Nano-sized particles typically tend to agglomerate, forming clusters that hinder their applications. Laboratory bead mills play a significant role in breaking apart these agglomerates and achieving homogeneity in particle dispersion. The grinding action of the beads effectively separates agglomerated particles, ensuring uniform distribution throughout the sample. This homogenization process is particularly essential in industries like paints and coatings, where uniformity is crucial for optimal performance.

4. Scalability and Reproducibility:

Laboratory bead mills not only offer exceptional performance on a small scale but also possess the potential for scalability. The parameters used in small-scale experiments can be translated to larger-scale production, ensuring reproducibility and consistency. This scalability is crucial for industries looking to commercialize nano-particles, as it allows for seamless transfer from lab-scale research to large-scale manufacturing.

Laboratory bead mills have emerged as vital tools in nano-particle research, offering precise control over particle size, enhanced reactivity, improved dispersion, and scalability. Their impact spans various industries, from biomedical research to materials science and more. As pioneers in laboratory bead mills, BOYEE continues to innovate and provide researchers with advanced solutions, revolutionizing the field of nano-particle research. Through a deep understanding of the significance and importance of laboratory bead mills, scientists can unlock the immense potential of nano-sized particles, leading to advancements in technology, medicine, and beyond.

Exploring the Mechanisms Behind the Breakthrough Efficiency of Bead Milling

Bead milling is a highly efficient method for the reduction of particle sizes to the nano-scale range. In the realm of laboratory procedures, this technique has gained significant popularity due to its ability to unleash the power of nano-sized particles. In this article, we will delve into the science behind laboratory bead mills, specifically focusing on the breakthrough efficiency of this process and the mechanisms that drive it.

Laboratory bead mills, such as those offered by BOYEE, are innovative instruments that utilize small glass or ceramic beads to disrupt samples and facilitate particle size reduction. These mills operate on the principle of shear force and impact, where the beads collide with the samples and break them down into smaller particles. The efficiency of this process is crucial for various scientific research applications, including pharmaceutical development, chemical engineering, and materials science.

One of the key factors contributing to the breakthrough efficiency of bead milling is the high shear rates achieved by these instruments. The shear rate defines the rate at which adjacent layers of a substance move relative to each other. In bead milling, the high shear rates exerted by the rotating beads effectively tear apart the samples, leading to a rapid reduction in particle size. BOYEE laboratory bead mills are equipped with advanced rotor-stator systems that generate intense shear forces, ensuring efficient particle size reduction.

Furthermore, laboratory bead mills offer excellent control over the milling parameters, allowing scientists to fine-tune the process according to their specific requirements. Parameters such as bead size, bead material, and milling time can be adjusted to optimize the efficiency and quality of particle size reduction. BOYEE's bead mills provide a wide range of options for bead sizes, allowing researchers to select the most suitable beads for their experiments. This versatility ensures that the milling process is tailored to achieve the desired outcomes.

In addition to shear force, laboratory bead mills also employ impact as a mechanism for particle size reduction. The collision between the beads and the samples generates a significant amount of energy that can break apart the particles. The high impact energy generated during bead milling ensures efficient fragmentation of the samples, further contributing to the breakthrough efficiency of this technique. BOYEE's laboratory bead mills are designed to maximize impact energy, enabling researchers to achieve precise and rapid particle size reduction.

Another crucial aspect of laboratory bead mills is their ability to maintain a stable and controlled environment for the milling process. These instruments offer efficient cooling mechanisms to prevent excessive heat generation, which could potentially alter the properties of the samples or compromise the efficiency of the milling process. BOYEE's bead mills incorporate advanced cooling systems that ensure consistent temperature control, guaranteeing reliable and reproducible results.

Furthermore, BOYEE's laboratory bead mills are equipped with state-of-the-art monitoring and control systems. These features enable researchers to monitor the milling process in real-time, providing valuable insights into the progress and efficiency of the particle size reduction. By closely monitoring the parameters and adjusting them accordingly, scientists can optimize the process and achieve the desired particle size distribution. BOYEE's commitment to cutting-edge technology ensures that researchers have access to the most advanced equipment for their scientific endeavors.

In conclusion, laboratory bead mills have revolutionized the field of particle size reduction by enabling the efficient and precise manipulation of nano-sized particles. Through the mechanisms of shear force and impact, these instruments unleash the breakthrough efficiency required for various scientific research applications. BOYEE's laboratory bead mills excel in delivering exceptional performance, offering scientists the tools they need to explore the realms of nano-sized particles and unlock new opportunities in scientific discovery.

Harnessing the Power of Nano-Sized Particles with Laboratory Bead Mills

In the realm of nanotechnology, laboratory bead mills have emerged as an essential tool for manipulating and harnessing the power of nano-sized particles. This article delves into the intricate science behind laboratory bead mills while highlighting the significant role they play in advancing nanotechnology research. As a leading provider of laboratory bead mills, BOYEE is committed to delivering cutting-edge technologies that empower scientists and researchers to unlock the full potential of nano-sized particles.

Understanding Laboratory Bead Mills:

Laboratory bead mills are highly sophisticated instruments designed to grind and disperse particles down to nanometer sizes. They utilize tiny beads, typically made of glass, ceramic, or steel, which impact and shear the particles, effectively reducing their size. These mills exhibit remarkable versatility, enabling precise control over parameters such as particle size, distribution, and material properties.

BOYEE: Pioneering Innovation in Nano-Sized Particle Manipulation:

As a trusted manufacturer in the realm of laboratory bead mills, BOYEE is well-known for its dedication to innovation and delivering cutting-edge technologies. With a diverse range of bead mills, BOYEE empowers researchers and scientists across various domains to refine their experiments and achieve groundbreaking advancements in nanotechnology.

Advanced Features of BOYEE Laboratory Bead Mills:

BOYEE's laboratory bead mills boast several key features that set them apart from conventional milling instruments. These features include but are not limited to:

1. High Precision and Efficiency: BOYEE bead mills offer exceptional precision when it comes to particle size reduction, allowing researchers to obtain uniform particles in the nanometer range. With high milling efficiency, they enable researchers to achieve desired results in significantly shorter timeframes.

2. Advanced Cooling Systems: BOYEE bead mills are equipped with efficient cooling mechanisms that prevent overheating during the milling process. This ensures the preservation of delicate samples, maintaining their integrity and preventing any unwanted transformations.

3. User-Friendly Interface: BOYEE's laboratory bead mills are designed with user convenience in mind. Their intuitive interfaces allow researchers to easily control and monitor various parameters, facilitating efficient experimentation and data collection.

Applications of Laboratory Bead Mills in Nanotechnology:

Laboratory bead mills find extensive applications across diverse fields of nanotechnology research. Some notable areas where these mills are employed include:

1. Pharmaceutical Research: Laboratory bead mills are crucial for pharmaceutical research, aiding in the development of drug delivery systems and nanoparticle-based therapies. By precisely controlling particle size and distribution, researchers can enhance drug efficacy and targeted delivery.

2. Material Science: Bead mills contribute significantly to the field of material science, allowing researchers to produce nanoparticles for advanced materials such as coatings, composites, and electronics. The ability to finely tune particle properties offers immense potential for tailoring material characteristics at the nanoscale.

3. Biotechnology and Life Sciences: Laboratory bead mills play a pivotal role in biotechnology and life sciences, enabling efficient cell disruption, DNA extraction, and homogenization. By manipulating particles at the nano-level, researchers can unlock new insights into cellular mechanisms and develop innovative biotechnological applications.

Laboratory bead mills are at the forefront of nano-sized particle manipulation, driving progress in various branches of nanotechnology research. BOYEE's dedication to innovation and its advanced range of laboratory bead mills have cemented the brand's position as a leader in the field. With their exceptional precision, efficiency, and user-friendly interfaces, BOYEE bead mills empower researchers and scientists to unravel the mysteries of nano-sized particles and revolutionize countless industries for the better.

Unveiling the Techniques and Technologies Used in Laboratory Bead Mills

Laboratory bead mills have revolutionized the field of particle size reduction, enabling scientists and researchers to unlock the power of nano-sized particles. These sophisticated machines play a crucial role in various industries such as pharmaceuticals, cosmetics, paints, and electronics. In this article, we will delve into the science behind laboratory bead mills, exploring the techniques and technologies that make them so effective in achieving precise particle size reduction.

At the forefront of laboratory bead mills is BOYEE, a renowned brand in the field. With their expertise, they have developed state-of-the-art equipment that combines cutting-edge technologies with precise techniques to meet the diverse needs of scientific research.

One of the fundamental techniques employed in laboratory bead mills is bead milling. It involves the grinding of particles suspended in a liquid medium by the movement of beads within a enclosed chamber. These beads can be made of various materials such as glass, ceramic, or stainless steel, depending on the specific requirements of the application.

BOYEE's laboratory bead mills leverage the principle of high-energy bead milling, which utilizes high-speed agitation to break down particles into smaller sizes. This technique ensures uniform distribution and effective grinding, resulting in optimal particle size reduction. Additionally, BOYEE's bead mills are equipped with advanced cooling systems to prevent overheating, ensuring the integrity of sensitive materials.

The technology behind laboratory bead mills is equally significant. BOYEE's equipment incorporates advanced control systems that provide precise control over parameters such as agitation speed, temperature, and bead size. These technological advancements allow scientists to achieve the desired particle size with exceptional accuracy and reproducibility.

Furthermore, BOYEE's laboratory bead mills are designed for easy operation and maintenance. The machines are equipped with user-friendly interfaces and intuitive controls, ensuring that scientists can focus on their research without worrying about complex machinery. Additionally, the equipment is robust and durable, built to withstand the rigors of continuous operation in a laboratory environment.

In addition to particle size reduction, laboratory bead mills offer several other advantages. They enable the homogeneous mixing of various materials, allowing scientists to create tailor-made formulations for specific applications. Moreover, the use of beads as grinding media eliminates the contamination that can occur with traditional grinding techniques, ensuring the purity and integrity of the final product.

BOYEE's laboratory bead mills are available in a range of sizes and configurations, catering to the diverse needs of scientific research. From benchtop models suitable for small-scale experiments to larger production-scale equipment, BOYEE provides solutions for every laboratory requirement. Their commitment to innovation and customer satisfaction has made them a trusted name in the industry.

In conclusion, laboratory bead mills are invaluable tools in the field of particle size reduction. BOYEE's advanced techniques and sophisticated technologies empower scientists and researchers to unlock the potential of nano-sized particles. With their focus on precision, control, and user-friendliness, BOYEE's laboratory bead mills are leading the way in achieving efficient and accurate particle size reduction.

Advancing Research and Innovation through the Science of Laboratory Bead Mills

In an era characterized by scientific advancements and innovation, laboratory bead mills have emerged as vital tools in the field of research. These specialized machines, designed to efficiently grind, disperse, and homogenize nano-sized particles, have revolutionized the way scientists conduct experiments and develop groundbreaking products. BOYEE, a leading brand in laboratory equipment, is at the forefront of advancing research and innovation through their state-of-the-art laboratory bead mills.

Understanding Laboratory Bead Mills:

Laboratory bead mills, also known as bead grinders or bead homogenizers, utilize tiny, spherical beads made of various materials - glass, ceramic, stainless steel, or even polymers - to effectively break down and grind particles into smaller sizes. These mills operate on the principle of high-speed agitation, where the beads collide with the sample material, resulting in efficient particle size reduction and dispersion.

Unleashing the Power of Nano-Sized Particles:

Nano-sized particles hold great potential in a wide range of scientific fields, including pharmaceuticals, biotechnology, materials science, and nanotechnology. In the pharmaceutical industry, for instance, precise control over particle size and distribution is crucial for drug delivery systems, as it directly impacts drug bioavailability and efficacy. Laboratory bead mills provide scientists with the means to achieve these control parameters, leading to the development of more effective medications.

Furthermore, in the field of nanotechnology, where properties at the nanoscale significantly differ from their bulk counterparts, laboratory bead mills play a pivotal role in the production of nanomaterials with tailored properties. These materials find applications in electronics, catalysis, energy storage, and environmental remediation, among others.

Key Features and Benefits of BOYEE Laboratory Bead Mills:

1. Versatility: BOYEE laboratory bead mills offer a wide range of modes and customizable options, allowing researchers to handle various sample types, including biological cells, tissues, and challenging materials. This versatility enables scientists to explore diverse applications and achieve desired outcomes.

2. Speed and Efficiency: With high-speed rotation and innovative designs, BOYEE laboratory bead mills ensure rapid and efficient particle size reduction, dispersion, and homogenization, saving valuable research time and enhancing overall productivity.

3. Safety and Contamination-Free Processing: BOYEE's laboratory bead mills are engineered with safety features to prevent cross-contamination and protect both the operator and the sample material. The use of high-quality materials, coupled with advanced sealing mechanisms, ensures optimal containment and prevents sample contamination.

4. Precise Control: BOYEE's advanced control systems provide scientists with the ability to precisely control process parameters such as temperature, speed, and bead size, ensuring reproducibility and accurate particle size distribution.

The science of laboratory bead mills has unlocked a wide array of possibilities in research and innovation. BOYEE's commitment to advancing these technologies has empowered scientists to explore the world of nano-sized particles and harness their potential in various fields. By providing versatile, efficient, and safe laboratory bead mills, BOYEE continues to drive scientific progress and contribute to the evolution of research and innovation worldwide.

Conclusion

In conclusion, after delving into the science behind laboratory bead mills and exploring the power of nano-sized particles, it is clear that these technological advancements have revolutionized various industries. With our company's 19 years of experience in the industry, we have witnessed firsthand the incredible potential and benefits offered by these innovative tools. By enabling researchers and scientists to manipulate and control particle sizes at the nanoscale, laboratory bead mills have opened up new avenues for scientific discoveries, advancements in materials science, and even breakthroughs in pharmaceutical formulations. As we continue to grow and evolve, we remain committed to staying at the forefront of this ever-evolving field, providing cutting-edge solutions and opportunities for our clients. With the power of nano-sized particles unleashed, the future holds limitless possibilities for scientific progress and innovation.

Saturday: 9:00AM~4:00 PM