Exploring The Advancements And Applications Of Laboratory Bead Mill Technology

Welcome to our in-depth exploration of the incredible advancements and wide-ranging applications of laboratory bead mill technology. In this article, we delve into the world of these powerful instruments, uncovering how they have revolutionized various industries and enabled groundbreaking research. Whether you are a scientist seeking to optimize your experiments, a pharmaceutical professional looking for reliable particle size reduction, or simply intrigued by cutting-edge lab equipment, join us on this captivating journey into the realm of laboratory bead mill technology.

The Evolution of Laboratory Bead Mill Technology: From Traditional Grinding Techniques to Cutting-Edge Solutions

Laboratory bead mills have come a long way in terms of technological advancements and applications. Over the years, the traditional grinding techniques used in laboratories have been revolutionized by innovative cutting-edge solutions. In this article, we will explore the advancements and applications of laboratory bead mill technology, focusing on the immense progress that has been made in this field.

The keyword of this article is "laboratory bead mill," and it is worth mentioning that BOYEE has emerged as a prominent player in the industry. With a drive for innovation and a commitment to delivering high-quality solutions, BOYEE has become a trusted name in the laboratory bead mill market.

Traditionally, grinding techniques in laboratories involved using mortar and pestle, hand-operated mills, or mechanical grinders. While these methods served their purpose, they often lacked precision, efficiency, and reproducibility. As scientific research and applications became more complex, the need for more advanced grinding technologies became apparent.

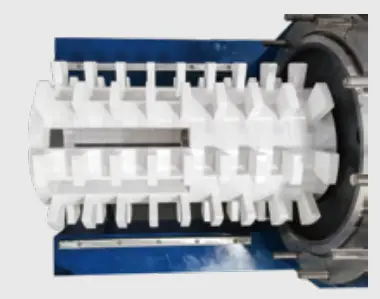

Enter the laboratory bead mill. This cutting-edge solution revolutionized the way scientists and researchers approached grinding in the laboratory. By introducing tiny beads into the grinding chamber, the bead mill provided a controlled and efficient method of particle size reduction. The principle behind the bead mill is based on the transfer of energy from the beads to the particles, effectively breaking them down into smaller sizes.

BOYEE, a pioneer in laboratory bead mill technology, has been at the forefront of these advancements. With a team of experienced engineers and technicians, BOYEE has developed state-of-the-art bead mills that offer precise control over the grinding process. These machines incorporate advanced features such as variable speed control, temperature regulation, and adjustable grinding chamber sizes, allowing researchers to optimize their experiments and achieve accurate results.

The applications of laboratory bead mill technology are vast and varied. In the field of pharmaceuticals, bead mills are used for drug formulation and development. By precisely grinding active pharmaceutical ingredients (APIs), researchers can optimize drug efficacy and improve patient outcomes. The ability to control particle size distribution is critical in achieving desired drug release profiles and ensuring consistent dosage.

Additionally, laboratory bead mills have found extensive use in the chemical industry, particularly in the production of pigments, dyes, and coatings. The precise control over particle size and uniformity offered by bead mills has significantly contributed to the development of high-quality products in these industries. By finely grinding raw materials, researchers can enhance color strength, improve dispersion, and achieve consistent product performance.

BOYEE's laboratory bead mills have been designed to meet the diverse needs of researchers across different industries. The company offers a range of models, each tailored to specific applications and requirements. With a focus on user-friendly design, BOYEE ensures that their bead mills are easy to operate, maintain, and clean, making them an ideal choice for any laboratory setting.

In conclusion, laboratory bead mill technology has undergone a remarkable evolution from traditional grinding techniques to cutting-edge solutions. BOYEE, with its commitment to innovation and excellence, has played a significant role in advancing this field. With their state-of-the-art bead mills and dedication to customer satisfaction, BOYEE has established itself as a leading name in laboratory bead mill technology. Researchers and scientists can now benefit from the precision, efficiency, and versatility offered by these machines, paving the way for groundbreaking discoveries and advancements in various industries.

Unveiling the Versatility of Laboratory Bead Mills: Key Applications in Research and Development

Laboratory bead mills have emerged as a versatile and indispensable tool in the field of research and development, facilitating numerous advancements and applications in various industries. This article aims to delve into the key applications of laboratory bead mills, showcasing the unparalleled versatility of this technology. As a leading brand in this field, BOYEE is at the forefront of manufacturing high-quality laboratory bead mills, providing researchers and scientists with innovative solutions.

1. Grinding and Dispersing Nanoparticles:

Laboratory bead mills are highly effective in grinding and dispersing nanoparticles, playing a crucial role in various research fields such as nanotechnology, materials science, and pharmaceuticals. With their precise control over particle size and distribution, these mills enable researchers to achieve homogenous and uniform dispersions, enhancing the quality and consistency of the end products.

2. Cell Disruption and Lysis:

In cell biology, laboratory bead mills have revolutionized the process of cell disruption and lysis. By subjecting cells to intense mechanical forces, laboratory bead mills rupture the cell membranes, releasing intracellular contents for further analysis and study. This enables researchers to access proteins, DNA, RNA, and other important intracellular components with higher yields and reduced processing time.

3. Homogenization of Biological Samples:

Laboratory bead mills also find extensive applications in the homogenization of biological samples, such as tissues and organs. By employing the appropriate bead size and duration of milling, researchers can achieve efficient disruption of sample matrices, ensuring uniform blending of different components. This homogenization process is vital for downstream applications like DNA extraction, protein purification, and metabolomic studies.

4. Formulation Development in Pharmaceuticals:

Pharmaceutical research heavily relies on laboratory bead mills for formulation development. These mills enable precise particle size reduction and distribution control, which have a significant impact on the drug's bioavailability, stability, and efficacy. From reducing active pharmaceutical ingredients to micronized sizes to formulating drug-loaded nanoparticles, laboratory bead mills allow for precise optimization of pharmaceutical formulations.

5. Paints and Coatings:

The versatility of laboratory bead mills is also evident in the paint and coating industry. These mills effectively disperse pigment particles into the paint medium, ensuring enhanced color strength, smoothness, and glossiness of the final product. Moreover, laboratory bead mills contribute to a reduction in the amount of solvent required, which makes it environmentally friendly and economically viable.

6. Manufacture of Personal Care Products:

From cosmetics to skincare, laboratory bead mills play a crucial role in the development and manufacture of personal care products. These mills aid in the dispersing and blending of various ingredients, ensuring uniform distribution and improved stability of formulations. Laboratory bead mills can disintegrate pigments, homogenize emulsions, and facilitate the incorporation of active ingredients, resulting in high-quality and aesthetically superior products.

Laboratory bead mills, with their exceptional versatility and applications, have become an indispensable tool in research and development. The innovative advancements in technology have significantly improved the efficiency and accuracy of various processes across industries such as nanotechnology, cell biology, pharmaceuticals, paints and coatings, and personal care products. As a trusted brand in the field, BOYEE provides cutting-edge laboratory bead mills, empowering researchers and scientists to break new ground in their respective domains.

Understanding the Working Principles of Laboratory Bead Mills: A Closer Look at the Grinding Process

Laboratory bead mills have become an integral part of the research and development process in various industries, including pharmaceuticals, biotechnology, and materials science. These machines offer a reliable and efficient method for particle size reduction, dispersion, and homogenization. In this article, we will delve into the intricacies of laboratory bead mills, focusing on the grinding process and how it contributes to advancements and applications in this technology.

A laboratory bead mill, such as the ones offered by BOYEE, is a specialized instrument used for grinding and dispersing solid materials into a liquid medium. It encompasses a cylindrical chamber filled with small grinding beads made of various materials such as glass, ceramic, or stainless steel. The mill's efficiency is dependent on the selection of these grinding beads and their size, as well as the operational parameters.

The grinding process employed by laboratory bead mills involves the continuous agitation of the grinding media and the sample material within the chamber. The rotational movement of the mill imparts kinetic energy to the grinding beads, creating a forceful impact and friction between the particles. This action results in the fragmentation and reduction of the solid material into smaller particles.

The effectiveness of the grinding process in a laboratory bead mill is heavily influenced by several factors. These factors include the bead size, bead material, sample concentration, viscosity, and the milling time. Adjusting these variables allows researchers to control the size distribution, shape, and surface characteristics of the final product.

One key advantage of laboratory bead mills is their ability to achieve narrow particle size distributions. This feature is particularly crucial in industries where consistent and precise particle sizes are required for optimal performance. By carefully selecting the appropriate grinding media and adjusting the milling parameters, researchers can obtain particles with sizes ranging from a few nanometers to several micrometers.

In addition to particle size reduction, laboratory bead mills excel in dispersion and homogenization. The intense grinding action within the milling chamber effectively breaks apart aggregations and agglomerates, ensuring uniform distribution of the sample materials in the liquid medium. This is vital for applications that demand the consistent dispersion of additives, pigments, or active pharmaceutical ingredients.

The advancements in laboratory bead mill technology have led to the development of more sophisticated and versatile instruments. BOYEE's range of laboratory bead mills, for example, incorporates advanced features such as temperature control, multiple milling modes, and programmable operation. These advancements offer researchers greater control and flexibility in achieving desired particle characteristics and optimizing process parameters.

The applications of laboratory bead mills span across various industries. In the pharmaceutical sector, these machines are used for drug formulation, nanoparticle synthesis, and controlled drug release systems. In biotechnology, they aid in cell disruption, protein extraction, and DNA isolation. In materials science, laboratory bead mills play a pivotal role in the production of advanced ceramics, paints, and coatings.

In conclusion, laboratory bead mills are essential tools for researchers in industries where particle size reduction, dispersion, and homogenization are critical. Understanding the working principles of these machines, along with advancements in technology, allows for precise control over the grinding process and the production of tailored particle characteristics. With BOYEE's range of innovative laboratory bead mills, researchers can confidently advance their work in various fields, driving progress and innovation.

Innovations in Laboratory Bead Mill Technology: Enhancing Efficiency, Control, and Scalability

Laboratory bead mills have emerged as crucial tools in the field of research and development, enabling scientists to efficiently grind, disperse, and homogenize various materials. These mills have undergone significant advancements in recent years, revolutionizing the way experiments are conducted in laboratories across numerous industries. This article delves into the advancements and applications of laboratory bead mill technology, with a focus on how these innovations have enhanced efficiency, control, and scalability.

Efficiency lies at the core of laboratory bead mill technology, and recent advancements have further optimized this aspect. Traditional milling methods often resulted in significant material loss due to excessive heat generation and uneven particle size distribution. However, with innovations like the BOYEE laboratory bead mill, researchers can now achieve higher levels of efficiency. The mill's unique design ensures efficient material transfer, reducing the risk of wastage and ensuring maximum utilization. Moreover, the improved cooling system prevents overheating, preserving the integrity of sensitive materials and leading to more accurate results.

Control is another critical element that has been greatly enhanced through innovations in laboratory bead mill technology. The BOYEE laboratory bead mill, for instance, offers precise control over speed, temperature, and time, allowing researchers to customize their experiments based on specific requirements. This level of control enables scientists to achieve consistent and reproducible results, leading to more reliable data and conclusions. With the ability to control the milling process at such granular levels, researchers can optimize their experiments, adapt to different sample types, and explore various milling strategies with ease.

Scalability is a key aspect for laboratories looking to transition from research and development to large-scale production. Advancements in laboratory bead mill technology have made scalability more feasible than ever. The BOYEE laboratory bead mill, with its modular design and flexible configurations, seamlessly adapts to changing production requirements. This means that researchers can easily transition from small-scale experiments in the lab to larger production volumes, without the need for significant investments in new equipment. This scalability not only saves time but also streamlines the development process, allowing for faster commercialization of new products.

One specific area where laboratory bead mill technology has found extensive applications is in the field of nanotechnology. Nanoparticles, which play a crucial role in various industries including electronics, pharmaceuticals, and cosmetics, require a meticulous manufacturing process to ensure their quality and functionality. Laboratory bead mills have proven to be indispensable tools in producing nanoparticles with consistent size distribution, narrow particle size ranges, and improved dispersion properties. With the advancements in laboratory bead mill technology, researchers can now achieve precise control over these parameters, making nanoparticles more accessible for a wide range of applications.

In conclusion, laboratory bead mill technology has undergone significant innovations, resulting in enhanced efficiency, control, and scalability. The BOYEE laboratory bead mill, with its efficient design, precise control features, and scalability options, has redefined the way experiments are conducted in various industries. These advancements have opened doors for further exploration and development, particularly in the field of nanotechnology. As the demand for high-quality and precisely controlled materials continues to rise, laboratory bead mills like the BOYEE will continue to play a pivotal role in the field of research and development.

Future Prospects: Expanding Applications and Potential Developments in Laboratory Bead Mill Technology

Laboratory bead mill technology has revolutionized the field of particle size reduction and dispersion in various industries. This innovative technology has gained significant momentum due to its efficient and precise nature, offering researchers and scientists greater control over particle size distribution and material properties. With continuous advancements and expanding applications, the future of laboratory bead mill technology holds immense potential for further development. In this article, we explore the various applications and potential developments in laboratory bead mill technology, with a special focus on the brand BOYEE.

Applications of Laboratory Bead Mill Technology:

1. Pharmaceutical Industry:

In the pharmaceutical industry, laboratory bead mills play a crucial role in drug development and formulation. These mills are used for milling, grinding, and homogenizing pharmaceutical ingredients to achieve desired particle size distribution and drug bioavailability. The precise control offered by laboratory bead mills assists in optimizing drug delivery systems and enhancing drug solubility, ultimately leading to improved therapeutic outcomes.

2. Biotechnology and Life Sciences:

Laboratory bead mills find extensive applications in the biotechnology and life sciences sector, particularly in the areas of cell disruption, DNA/RNA extraction, and protein extraction. The gentle and efficient cell lysis provided by bead mills ensures maximum yield of valuable intracellular components without compromising their integrity. The resulting homogenates serve as a basis for further downstream analyses, such as PCR, Western blotting, and enzyme activity assays.

3. Chemical and Coating Industries:

With the increasing demand for fine and nano-scale particle production, laboratory bead mills have become a valuable tool in the chemical and coating industries. These mills enable precise control over particle size and distribution, allowing manufacturers to enhance the performance and stability of their products. Bead mill technology facilitates the production of high-quality paints, ink dispersions, and pigment formulations, resulting in improved color strength, gloss, and durability.

Potential Developments in Laboratory Bead Mill Technology:

1. Enhanced Automation:

As technology continues to evolve, laboratory bead mills hold potential for further automation. Automation of various parameters, such as speed, temperature, and bead size, would improve repeatability and enable more efficient and reproducible results. BOYEE, as a market leader, is at the forefront of implementing automation features to streamline laboratory processes and enhance productivity.

2. Integration of Real-time Monitoring:

Integrating real-time monitoring capabilities into laboratory bead mills could facilitate on-the-spot analysis of particle size and distribution. This would enable researchers to make informed decisions during the milling process, ultimately saving time and resources. BOYEE is actively exploring ways to incorporate real-time monitoring technologies like laser diffraction and dynamic light scattering into their bead mills.

3. Versatility and Customization:

Future developments in laboratory bead mill technology are likely to focus on providing greater versatility and customization options to meet diverse research requirements. BOYEE, as an industry leader, is committed to offering customizable bead mills that cater to specific applications and research needs.

Laboratory bead mill technology has already made significant advancements in various industries, such as pharmaceuticals, biotechnology, and coatings. The future prospects of this technology are promising, with potential developments including enhanced automation, real-time monitoring, and increased versatility. BOYEE, as a leading brand in the laboratory bead mill market, is dedicated to driving innovation and ensuring researchers and scientists have access to state-of-the-art equipment to push the boundaries of their research.

Conclusion

In conclusion, the advancements and applications of laboratory bead mill technology have revolutionized the field of scientific research and industrial production. With our 19 years of experience in the industry, we have witnessed firsthand the incredible impact that this technology has had on various sectors. From pharmaceuticals and biotechnology to paints and coatings, laboratory bead mills have proven to be indispensable tools for achieving precise and efficient particle size reduction. By enabling researchers and manufacturers to finely control the size and distribution of particles, these mills facilitate the development of innovative products and processes that improve our daily lives. As we continue to explore and harness the potential of laboratory bead mill technology, we are excited to witness further advancements and applications that will shape the future of scientific and industrial progress.

Saturday: 9:00AM~4:00 PM