TopBOYEE Industrial Dispersion Tank - 7.7

Product details of the industrial dispersion tank

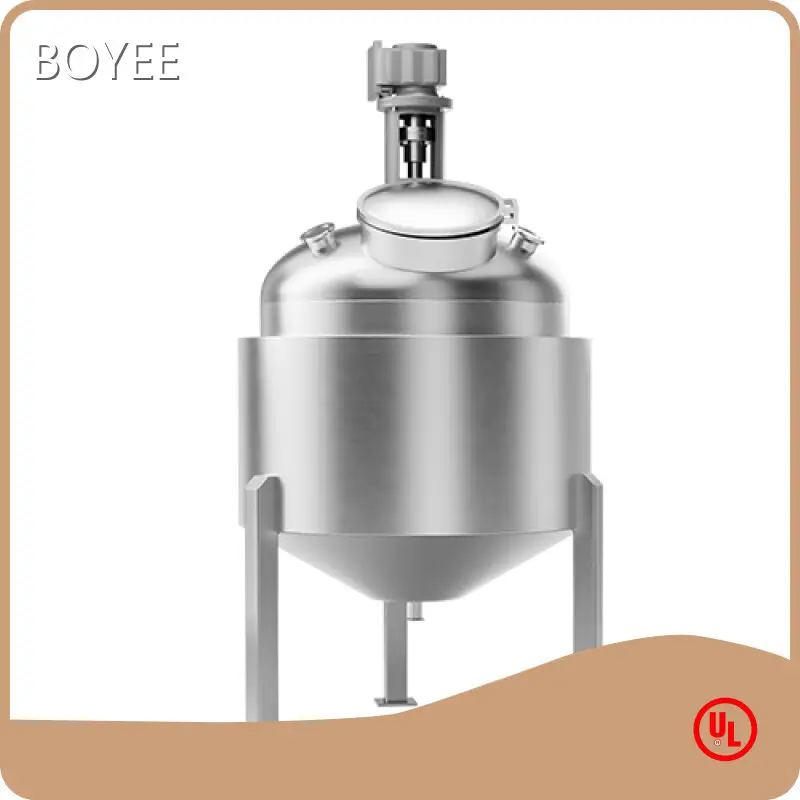

Product Introduction

The texture of industrial dispersion tank is often a major determinant of how well a product is designed. industrial dispersion tank produced by the factory has high technological content, reasonable structure and superior performance. With superior quality and industrial dispersion tank, BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD wins warm praise from customers.

Product Description

Boyee dispersion tanks can achieve better dispersion and homogeneity in less time. The external circulation piping design ensures the uniform dispersion of the material in the tank, which makes our dispersion tank can easily meet more difficult dispersion challenges. The tank and the disperser are flange sealed and welded together to provide a high quality seal, ensuring a hygienic and dust-free dispersing operation.

In addition, the choice of disperser is flexible and the automation module can be freely configured according to your production process to meet your individual needs.

Product Advantages

● Flexible configuration of disperser

● High quality stainless steel for contact parts

● Supports automated module configuration

● No additional cleaning work

Product Parameters

| Volume(L) | Tank diameter(mm) | Stirring power(KW) | Stirring speed(r/min) | Work pressure(Mpa) |

| 20 | 300 | 0.2 | 130 | ≤0.3 |

| 50 | 450 | 1.1 | 130 | ≤0.3 |

| 100 | 500 | 1.1 | 85 | ≤0.3 |

| 200 | 700 | 1.5 | 85 | ≤0.3 |

| 300 | 900 | 3 | 85 | ≤0.3 |

| 500 | 1000 | 4/5.5 | 76 | ≤0.3 |

| 1,000 | 1200 | 5.5 | 63 | ≤0.3 |

| 2,000 | 1400 | 7.7 | 63 | ≤0.3 |

| 3,000 | 1500 | 11 | 63 | ≤0.3 |

| 6,000 | 2200 | 18.8 | 63 | ≤0.3 |

| 10,000 | 2400 | 18.5 | 63 | ≤0.3 |

Product Features

Thanks to the major breakthrough of Boyee dispersion tank, our dispersion tanks can easily meet more difficult dispersion

challenges and achieve better dispersion and homogeneity in less time.

Product Application

Faqs

Rod-pin type bead mills, also known as rod-pin horizontal bead mills, have some distinct characteristics and applications compared to other types of bead mills. Here are some of the key features and applications of rod-pin type bead mills:

Grinding mechanism: Rod-pin type bead mills use a combination of rods and pins as the grinding media, which provides a more efficient and homogeneous grinding action compared to other types of bead mills. The rods and pins rotate at high speeds within the grinding chamber, causing the material to be ground by both shear and impact forces.

Narrow particle size distribution: Rod-pin type bead mills are particularly effective at producing narrow and uniform particle size distributions, due to the efficient grinding mechanism and the use of high-quality grinding media. This makes them suitable for a wide range of applications that require precise particle size control, such as inks, pigments, coatings, and pharmaceuticals.

High throughput: Rod-pin type bead mills are capable of achieving high throughput rates, due to the combination of efficient grinding action and the use of large-volume grinding chambers. This makes them suitable for large-scale production of high-quality dispersions and suspensions.

Versatility: Rod-pin type bead mills can be used for a wide range of materials and applications, including aqueous and solvent-based formulations, as well as high-viscosity materials. They are also suitable for processing heat-sensitive materials, due to the efficient cooling provided by the cooling jacket surrounding the grinding chamber.

Easy maintenance and cleaning: Rod-pin type bead mills are designed for easy maintenance and cleaning, with simple and accessible components that can be easily removed and replaced. This reduces downtime and increases productivity, as well as ensuring the long-term reliability and performance of the machine.

Grinding chamber design: The design of the grinding chamber in rod-pin type bead mills is typically optimized for maximum grinding efficiency and uniformity. The grinding chamber is often cylindrical in shape, with a cooling jacket surrounding the chamber to prevent overheating. The rods and pins are typically arranged in a staggered pattern, to ensure maximum contact with the material being ground.

Control and automation: Rod-pin type bead mills often come with advanced control and automation features, such as programmable settings, digital readouts, and real-time monitoring of key parameters such as temperature, pressure, and flow rate. This helps to ensure accurate and consistent grinding results, and allows for efficient optimization of the grinding process.

Size range and capacity: Rod-pin type bead mills are available in a range of sizes and capacities, to suit different application requirements. They can handle batch sizes ranging from a few milliliters up to several liters or more, and are capable of producing high-quality dispersions or suspensions with particle sizes in the submicron range.

Material compatibility: Rod-pin type bead mills are suitable for processing a wide range of materials, including organic and inorganic pigments, dyes, fillers, and various types of nanoparticles. They can also be used for grinding natural materials such as plant extracts, minerals, and ores.

Maintenance and cleaning: Rod-pin type bead mills are designed to be easy to maintain and clean, with simple and accessible components that can be easily removed and replaced. This helps to minimize downtime and ensure long-term reliability and performance of the machine. Regular cleaning and maintenance are important to prevent contamination and ensure consistent grinding results.

In summary, rod-pin type bead mills are characterized by their efficient grinding mechanism, narrow particle size distribution, high throughput, versatility, and easy maintenance and cleaning. They are suitable for a wide range of applications and materials, including inks, pigments, coatings, and pharmaceuticals, where precise particle size control and high-quality dispersions or suspensions are required. and come in a variety of sizes and capacities. Advanced control and automation features help to ensure accurate and consistent grinding results.

Company Advantage

• Since it was established in our company has been focusing on the research and development and production of main products for years. So far, we have accumulated a large amount of professional knowledge and rich production experience.

• Our company has further optimized the export environment and the export volume of products has increased greatly. We mainly export our products to some countries and regions in Southeast Asia, South America and Africa.

• Our company has advanced technical support and perfect after-sales service, so that customers can select and purchase without worries.

• BOYEE owns a superior geographical location. There are traffic convenience, elegant ecological environment, and abundant natural resources.

Thanks for visiting. BOYEE will provide various product information and help you further understand the industry.

Saturday: 9:00AM~4:00 PM