Newbead Mill for Cell DisruptionBOYEE Company

Company Advantages

· For the design of BOYEE bead mill for cell disruption, we have a professional design team to take responsibilities for it.

· bead mill for cell disruption is a product which has many qualities and has a large assortment of applications it is suitable for.

· The potential value of the product makes it applicable in multiple scenarios.

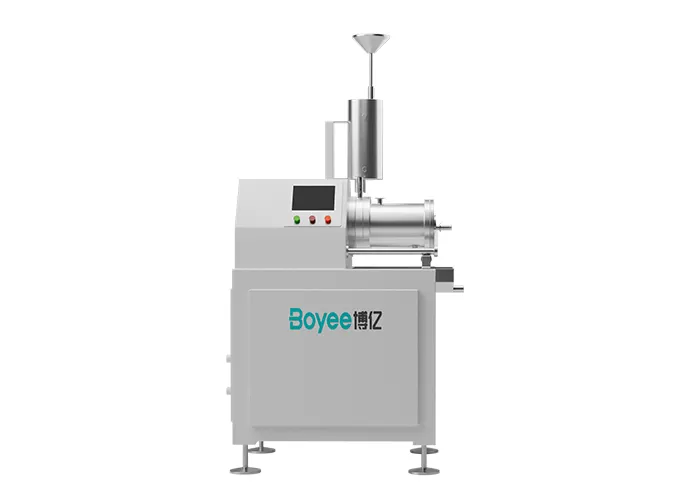

Product Display

Product Description

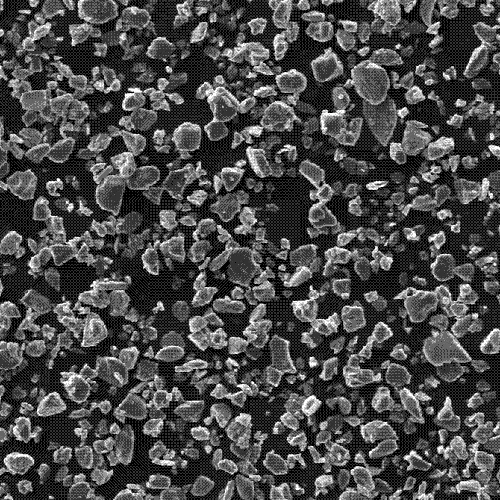

This model is suitable for small-scale testing and formulation development in laboratory-scale processes, catering to different grinding needs with its versatile functionality. It can achieve a minimum grinding media size of 0.1mm, making it an essential equipment for your experimental work.

Product Advantages

● Suitable for small scale grinding and production in laboratory.

● The minimum grinding media size is as small as 0.1mm.

● Multiple options for internal structural material selection, catering to different material requirements.

● The experimental data can be scaled up for production

● The whole machine adopts stainless steel structure, strong acid and alkali resistance

Product Parameters

| Model | Volume(L) | Power(KW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| NMM-1L | 1 | 2.2 | 0-2960 | 0.1-1 | 150 | 1000×580×1750 |

| NMM-2L | 2 | 4.5 | 0-2960 | 0.1-1 | 260 | 1200x800x1800 |

Product Features

This model is suitable for small-scale testing and formulation development in laboratory-scale processes, catering to different grinding needs with its versatile functionality. It can achieve a minimum grinding media size of 0.1mm, making it an essential equipment for your experimental work.

Product Application

Faqs

Beads wear out quickly: One common problem with the bead mill is that the grinding beads wear out quickly, which can result in reduced efficiency and increased operating costs. To address this problem, it is important to choose high-quality grinding beads that are appropriate for the material being processed. Additionally, the bead mill should be operated at the recommended speed and with the appropriate amount of bead filling to minimize wear.

Clogging of the grinding chamber: Another common problem with the bead mill is the clogging of the grinding chamber due to the accumulation of material or improper bead size distribution. This can be addressed by adjusting the bead size distribution, reducing the feed rate, or installing a pre-grinding process to reduce the particle size of the material before it enters the bead mill.

Overheating of the grinding chamber: Overheating of the grinding chamber can occur due to excessive friction and can result in the degradation of the material being processed and reduced efficiency. To address this problem, it is important to monitor the temperature of the grinding chamber and adjust the cooling system as needed. This may involve adjusting the coolant flow rate, using a different cooling medium, or installing additional cooling elements.

Inconsistent particle size distribution: Inconsistent particle size distribution can occur due to a variety of factors, including improper bead size distribution, improper bead filling, and improper operating conditions. To address this problem, it is important to optimize the bead size distribution and filling, adjust the operating parameters as needed, and monitor the particle size distribution regularly.

Mechanical failure: Mechanical failure of the bead mill can occur due to wear and tear on the mill components or improper maintenance. To address this problem, it is important to perform regular maintenance on the bead mill, including cleaning, lubrication, and replacement of worn components. It is also important to use high-quality components and to follow the manufacturer's recommended maintenance schedule.

Foaming: Foaming can occur due to the formation of air bubbles during the milling process, which can result in reduced efficiency and inconsistent product quality. To address this problem, it is important to adjust the milling conditions to minimize the formation of air bubbles, such as reducing the milling speed or adjusting the flow rate of the cooling medium.

Contamination: Contamination can occur due to the wear and tear of the mill components or improper cleaning and maintenance procedures. To address this problem, it is important to use high-quality materials for the mill components, regularly clean and sanitize the mill, and follow proper maintenance procedures.

Poor dispersion: Poor dispersion can occur due to a variety of factors, including improper bead size, improper bead filling, and improper operating conditions. To address this problem, it is important to optimize the bead size and filling, adjust the operating parameters as needed, and monitor the dispersion quality regularly.

Power consumption: High power consumption can occur due to inefficient milling conditions or improper operating parameters. To address this problem, it is important to optimize the milling conditions, adjust the operating parameters as needed, and monitor the power consumption regularly.

By addressing these common problems and implementing appropriate solutions, users can optimize the performance and efficiency of their bead mill and improve the quality of their products.

Company Features

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD mainly produces various kinds of bead mill for cell disruption.

· Being professional in producing bead mill for cell disruption, BOYEE owns highly developed technology. Many customers have shown their great interest in our bead mill for cell disruption. The implementation of the most advanced technology greatly improves the quality of bead mill for cell disruption.

· We have set up one ambitious goal. We will take the lead in the bead mill for cell disruption industry in the coming years. By implementing quality strategies, we will upgrade all processes from raw materials to packaging.

Application of the Product

The bead mill for cell disruption produced by our company is widely recognized by customers and widely used in field.

Our company will modify and adjust the original solution according to the customer's needs. By doing so, we can provide solutions that best meet the customer's needs.

Product Comparison

BOYEE guarantees Bead mill to be high-quality by carrying out highly standardized production. Compared with other products in the same category, it has the following advantages.

Saturday: 9:00AM~4:00 PM