Latestbead Mill for Cell DisruptionBOYEE Company

Product details of the bead mill for cell disruption

Product Information

The modern manufacture technology guarantees the production of BOYEE bead mill for cell disruption. With the comprehensive process visualization across all production stages, the product is guaranteed to be zero-defect. BOYEE has been focusing on the business of offering bead mill for cell disruption.

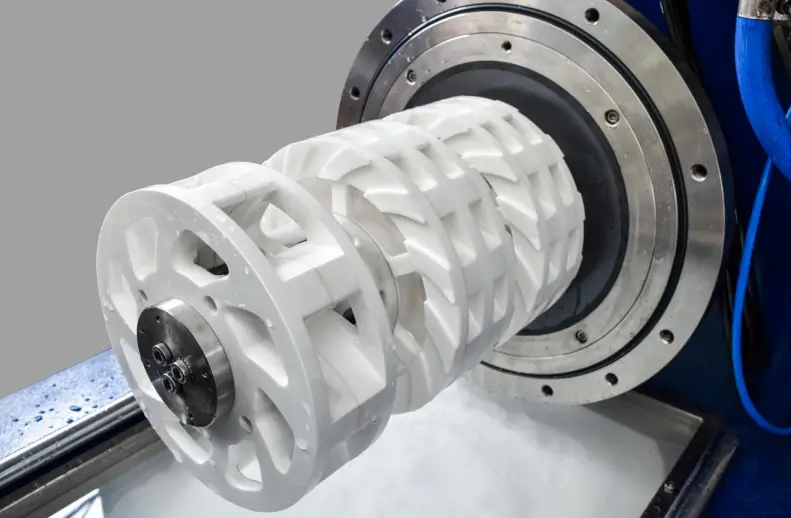

Product Display

Product Description

The BYZr bead mill adopts the TurboMax turbo grinding structure, which effectively prevents excessive dispersion of materials, improves the grinding media, reduces energy consumption, enhances the wear resistance of ceramic components, ensures greater equipment stability, and extends its lifespan while maintaining low maintenance costs.

Product Advantages

● Turbo type grinding structure for more refined grinding effect

● High grinding efficiency, large output and low energy consumption

● It is suitable for nano-level grinding of medium and low viscosity materials

● All ceramic accessories grinding material, reduce material pollution

● High flow flexible grinding, concentrated particle size, no damage to material morphology

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Media diameter (mm) | Weight (kg) | Size (mm) |

| BYZr-3L | 2.2 | 7.5 | 0-1450 | 0.3-1 | 468 | 1200×1050×1450 |

| BYZr-15L | 11 | 30 | 0-1860 | 0.3-1 | 1205 | 1600×1350×1850 |

| BYZr-30L | 22 | 37-45 | 0-1325 | 0.3-1.2 | 1425 | 1750×1350×1850 |

Product Features

BYZr ceramic turbo bead mill is a Chinese nano-level all-ceramic turbo bead mill independently developed by Boyee. It ensures the grinding material material zero pollution. With the built-in hollow shaft and turbo structure, it enables flexible grinding without damaging the morphology of the material, resulting in superior grinding performance.

Product Application

Faqs

The bearing is an essential component of the bead mill. Proper installation and maintenance of bearings can ensure the smooth operation of the machine. Here are some tips for bearing installation and maintenance.

Proper installation: Before installing the bearing, make sure that the bearing housing and the shaft are clean and free of any dirt or debris. Lubricate the bearing with a high-quality lubricant before installation. Also, ensure that the bearing is correctly seated in the housing and the shaft, and the fit is not too tight or too loose.

Regular maintenance: Regularly check the condition of the bearing and the lubricant. If there are any signs of wear or damage, replace the bearing immediately. Also, periodically lubricate the bearing with a high-quality lubricant to ensure smooth operation.

Temperature monitoring: Monitor the temperature of the bearing regularly. If the temperature of the bearing exceeds the recommended limit, stop the machine immediately and investigate the cause of the high temperature.

Bearing alignment: Proper alignment of the bearing is crucial for the smooth operation of the bead mill. Misalignment can cause excessive wear and tear on the bearing, leading to premature failure. Therefore, check the bearing alignment regularly and adjust it as necessary.

Cleanliness: Keep the bearing and its surrounding area clean and free of any debris or contaminants that can cause damage to the bearing.

Proper installation and maintenance of the bearing can help extend the life of the bead mill and prevent costly breakdowns.

Company Feature

• Our company owns independent technology research and development team and professional technical engineers. They put the innovative research and development concept into every aspect of product design, production and development.

• Established in BOYEE has years of production experience.

• BOYEE's Bead mill gain a relatively large market share in China. They are also exported to Africa, Southeast Asia, and other countries and regions.

BOYEE provides you with latest industry information.

Saturday: 9:00AM~4:00 PM