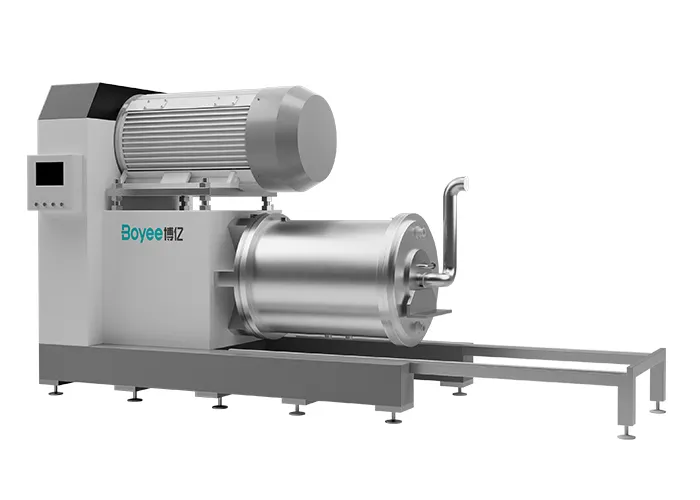

BOYEE Glass Bead Mill 4500×1700×2400 Glass Bead MillSupply

Product details of the glass bead mill

Product Overview

BOYEE glass bead mill is designed to create an original look that is truly unique. Every stage of the production process is strictly monitored to ensure the quality of this product. The glass bead mill developed by our company can play a role in various fields. This product has a wide range of practical and commercial applications.

Product Introduction

The details of glass bead mill are shown for you at below.

Product Display

Product Description

Boyee's patented TurboMax turbo and rod pin grinding systems effectively enhance grinding quality and precision, reduce cost of losses, and improve production efficiency.

Product Advantages

● Exceptional capability in handling high viscosity materials.

● Widely used in the market for grinding and dispersion of a variety of materials

● Smooth material discharge without blockages, meeting the requirements for large-scale production.

● Optional to Boyee TurboMax patented turbo and rod pin grinding systems

● Ceramic, polymer and alloy components are available

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Mediadiameter (mm) | Weight (kg) | Size (mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | ≥0.2 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

Product Features

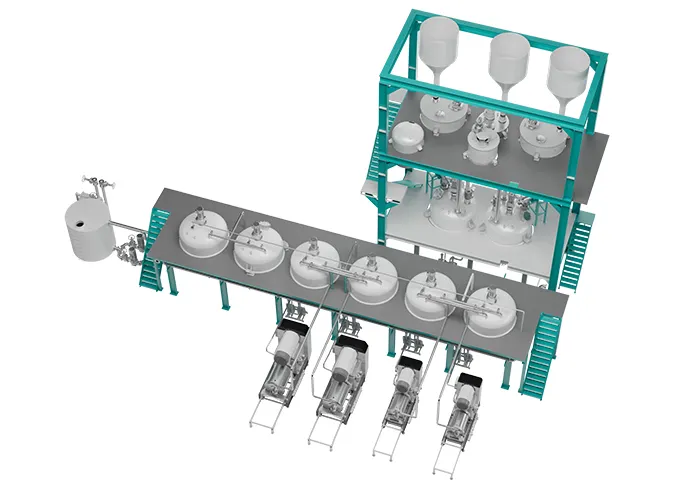

The high-flow screen-based nano bead mill is an ideal choice for grinding a large quantity of nano materials. You can choose between Boyee's patented TurboMax turbo or rod pin grinding system, which offers high grinding efficiency and short processing time, meeting the demands of large-scale production for businesses.

Product Application

Faqs

The operating parameters of a bead mill can vary depending on the specific equipment and application, but here are some general parameters to consider:

Bead size: The size of the beads used in the bead mill can impact the performance of the equipment. Bead size is typically measured in microns, and the appropriate size will depend on the material being processed.

Bead density: The density of the beads can impact the energy required to mill the material. Higher density beads may require more energy to mill the material, but they can also result in a finer particle size.

Milling time: The amount of time that the material is milled can impact the particle size and distribution. Longer milling times can result in smaller particle sizes, but they may also result in more heat generation and wear on the equipment.

Milling speed: The speed of the agitator in the bead mill can impact the performance of the equipment. Higher speeds can result in higher energy inputs and smaller particle sizes, but they can also result in more wear on the equipment.

Flow rate: The flow rate of the material through the bead mill can impact the performance of the equipment. Higher flow rates can result in higher energy inputs and smaller particle sizes, but they can also result in more wear on the equipment.

Cooling rate: The cooling rate of the material can impact the performance of the equipment. Proper cooling is essential for preventing overheating and ensuring optimal performance.

Material properties: The properties of the material being processed can impact the performance of the equipment. Factors such as viscosity, density, and particle size can all affect the milling process. It is important to consult the manufacturer's instructions and recommendations for specific operating parameters for the bead mill being used. The optimal operating parameters will depend on the specific application and material being processed.

Media loading: The amount of media (beads) loaded into the mill can impact the milling efficiency and particle size. It is important to load the appropriate amount of media for the specific application.

Container size: The size of the container (or grinding chamber) can impact the efficiency of the milling process. A larger container can handle larger volumes of material, but it may also require more energy to mill the material.

Agitation: The level of agitation in the bead mill can impact the milling efficiency and particle size. Proper agitation is essential for ensuring that all of the material is exposed to the milling media.

Solvent type: The type of solvent used in the milling process can impact the performance of the equipment. Different solvents may be required for different materials and applications.

Material feed rate: The rate at which the material is fed into the bead mill can impact the milling efficiency and particle size. It is important to maintain a consistent feed rate to ensure optimal performance.

Cooling system: Bead mills generate a lot of heat during operation, and excessive heat can affect the quality of the final product. Some bead mills are equipped with a cooling system to regulate the temperature of the milling chamber.

Dispersing time: The length of time that the material is subjected to milling can impact the particle size and distribution. Longer milling times can result in smaller particle sizes, but can also lead to excessive heat and wear on the equipment.

Cleaning: Proper cleaning and maintenance of the bead mill is essential for optimal performance and longevity. It is important to follow the manufacturer's recommended cleaning procedures and to remove any residue or buildup that can accumulate in the milling chamber.

Monitoring: Regular monitoring of the milling process is important to ensure that the equipment is operating correctly and that the desired particle size and distribution is being achieved. It may be necessary to make adjustments to the operating parameters during the milling process to maintain optimal performance.

Safety: Bead mills can be hazardous to operate, and it is important to follow all safety guidelines and precautions. Operators should be trained in the proper use of the equipment, and appropriate personal protective equipment should be worn at all times.

Proper selection and adjustment of these operating parameters can help optimize the performance of the bead mill and achieve the desired particle size and distribution. It is important to consult the manufacturer's recommendations and guidelines for the specific equipment being used.

Company Advantages

BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD mainly deals with the production and processing of Bead mill. BOYEE insists on the service concept to give priority to customer and service. We are dedicated to providing high-quality products and excellent services. Sincerely welcome customers who have needs to contact us for negotiation. I hope we can work together to create a brilliant future.

Saturday: 9:00AM~4:00 PM