BOYEE Brand Laboratory Bead Mill Supplier

Company Advantages

· BOYEE laboratory bead mill is a well-crafted product that adopts advanced technologies.

· Since we always adhere to the 'quality first', the quality of the products is fully guaranteed.

· This offered product is highly preferred by our customers in the global market.

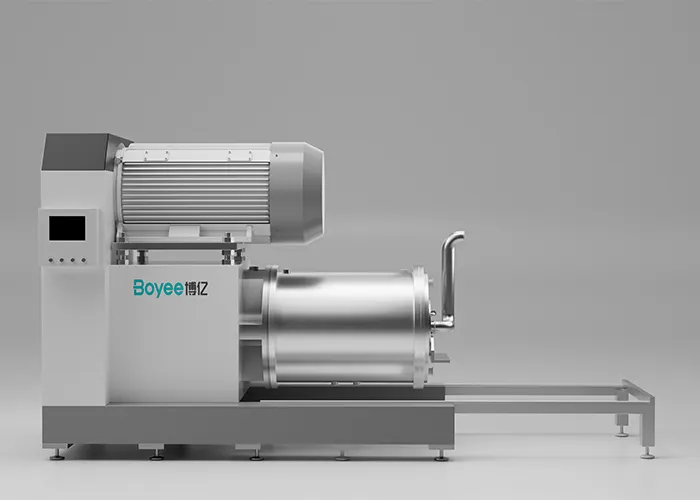

Product Display

Product Description

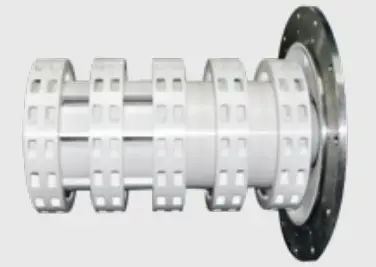

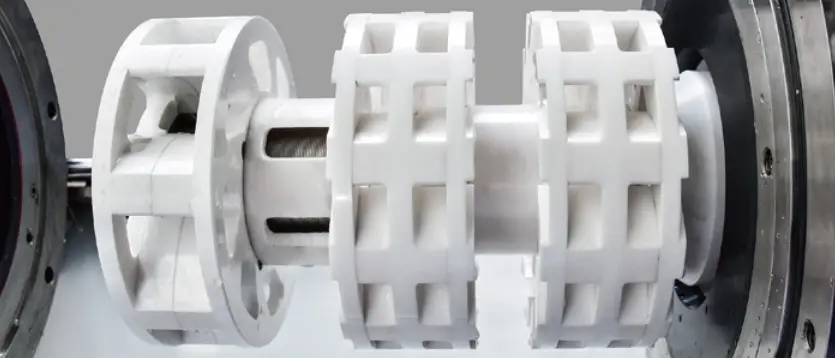

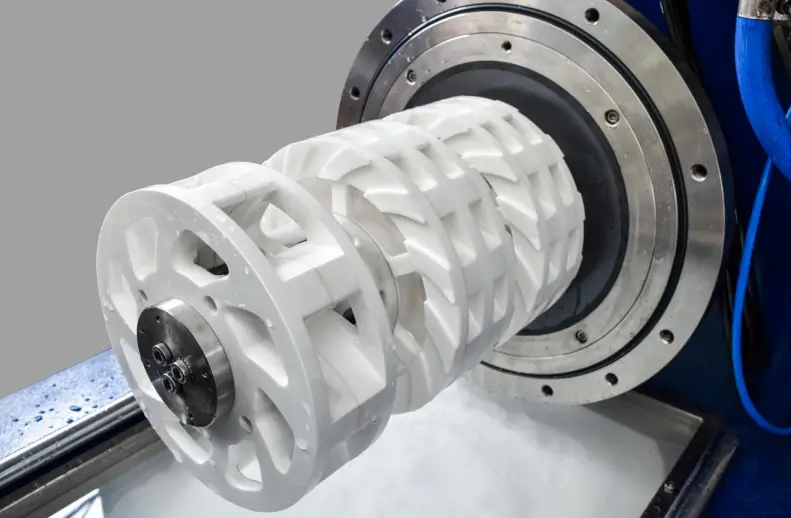

The screen-type bead mill, which is favored for handling high-viscosity materials, overcomes the traditional clogging problem. It is equipped with Boyee's independently developed TurboMax turbine structure, providing excellent operational stability, higher equipment flow, improved production efficiency, and reduced costs.

Product Advantages

● Higher flow

● High-quality handling capability for high-viscosity materials.

● Optional TurboMax turbine and rod pin grinding system.

● Optional ceramic, polymer, and alloy material components.

● Longer screen lifespan.

● All models meet the requirements from laboratory to large-scale production.

● Daily maintenance is simple and quick.

● Low noise impact.

Product Parameters

| Model | Volume (L) | Power (KW) | Speed (r/min) | Mediadiameter (mm) | Weight (kg) | Size (mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | ≥0.2 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

Product Features

Boyee TurboMax patented turbine and rod-pin grinding system can deliver energy to the grinding medium before achieving nano-level grinding and dispersion effects.

Product Application

Faqs

In a bead mill, the terms "dynamic discharge" and "static discharge" refer to two different methods of discharging the ground material from the mill.

Dynamic discharge, also known as pump or forced discharge, involves using a pump to force the material out of the mill through a discharge valve. This method is typically used with higher viscosity materials or materials that tend to stick to the walls of the mill, as it can help ensure a more complete discharge of the material and prevent clogging.

Static discharge, on the other hand, relies on gravity to discharge the material from the mill. In this method, the mill is tilted or inclined at an angle, allowing the ground material to flow out through a discharge port located at the bottom of the mill. This method is typically used with lower viscosity materials or materials that are less likely to stick to the walls of the mill, as it may not be as effective at ensuring a complete discharge of the material.

Overall, the choice of discharge method depends on the specific characteristics of the material being processed and the requirements of the application. Both dynamic and static discharge can be effective for different types of materials and applications, and it's important to choose the method that will provide the best results for your specific situation.

One important factor to consider when choosing between dynamic and static discharge is the viscosity of the material. Materials with higher viscosity may require dynamic discharge to ensure a more complete discharge of the material and prevent clogging. However, dynamic discharge may not be as effective with lower viscosity materials, which may flow more easily through a static discharge system.

Another factor to consider is the particle size of the material. Materials with larger particle sizes may require dynamic discharge to ensure that the larger particles are properly ground and discharged from the mill. Conversely, smaller particle sizes may be more effectively discharged through a static discharge system.

The specific requirements of the application may also play a role in determining the best discharge method. For example, if a continuous flow of material is required, dynamic discharge may be more appropriate. However, if batch processing is being used, static discharge may be more convenient.

Another important factor to consider when choosing between dynamic and static discharge is the nature of the material being processed. Some materials may be more prone to clogging or buildup within the mill, which can affect the efficiency of the grinding process and the effectiveness of the discharge method.

For example, materials that contain high levels of solids or other impurities may be more prone to clogging, making dynamic discharge more necessary. In contrast, materials that are more homogenous and free of impurities may be better suited for static discharge.

The specific design of the bead mill can also play a role in determining the most effective discharge method. Some bead mills may be specifically designed for dynamic discharge, while others may be better suited for static discharge.

Overall, the choice between dynamic and static discharge will depend on a variety of factors, including the nature of the material being processed, the design of the bead mill, and the specific requirements of the application. By carefully evaluating these factors and choosing the most appropriate discharge method, it's possible to optimize the performance of the bead mill and achieve the desired grinding results.

Company Features

· As a qualified supplier of laboratory bead mill, BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD has accumulated rich experience in product design, manufacture, and export.

· laboratory bead mill is created by the revolutionary technology. Processed by large technologies, laboratory bead mill enjoys an excellent performance in the field.

· There are two important points that are central to our business activity: Meet the requirements of the regulations and control the environmental risks. Strive for continual improvement of environmental accomplishments. Inquire online!

Product Details

BOYEE's laboratory bead mill is exquisite in details.

Application of the Product

laboratory bead mill of BOYEE has very extensive application in different scenarios.

BOYEE has established a professional technical team. They can provide customers with targeted processes and solutions. Based on this, the problems of customers can be better solved.

Product Comparison

After improvement, the laboratory bead mill produced by BOYEE is more brilliant in the following aspects.

Enterprise Advantages

Our company has a strong technical team engaged in independent innovation. Meanwhile, we actively strengthen cooperation with domestic research institutes. Apart from that, we recruit well-known experts in the industry as senior consultants. All that provides strong technical support for our development.

With the service concept of 'customer first, service first', BOYEE constantly improves the service and strive to provide professional, high-quality and comprehensive services for customers.

With the main focus on quality, BOYEE strives for excellence and steady development. We think highly of integrity and sincerity, which is the foundation for us to gain mutual benefit. Strict quality control and focus on customers are of great importance to corporate development. We strive to build a first-class brand and become a leader in the industry.

BOYEE, established in has mastered advanced technology in industry. With the growth of years, we can well meet customer requirements now.

BOYEE's Bead mill are deeply trusted by customers. They occupy a large market share in China and are exported to Europe, America, Southeast Asia, and other countries and regions.

Saturday: 9:00AM~4:00 PM