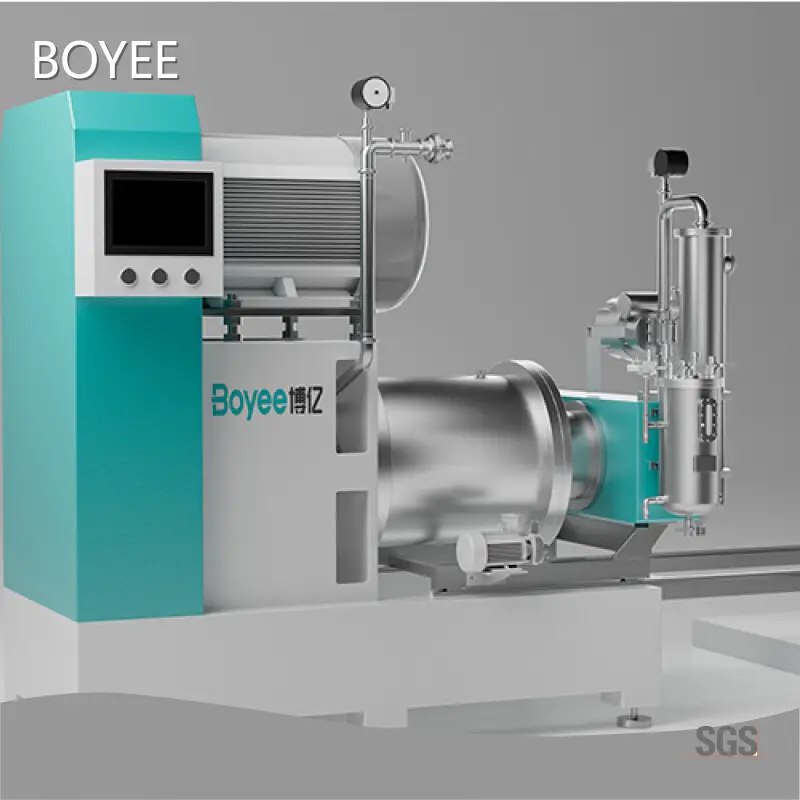

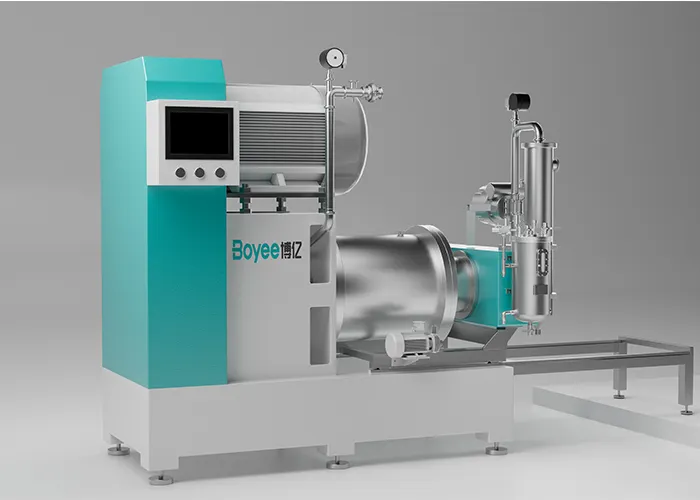

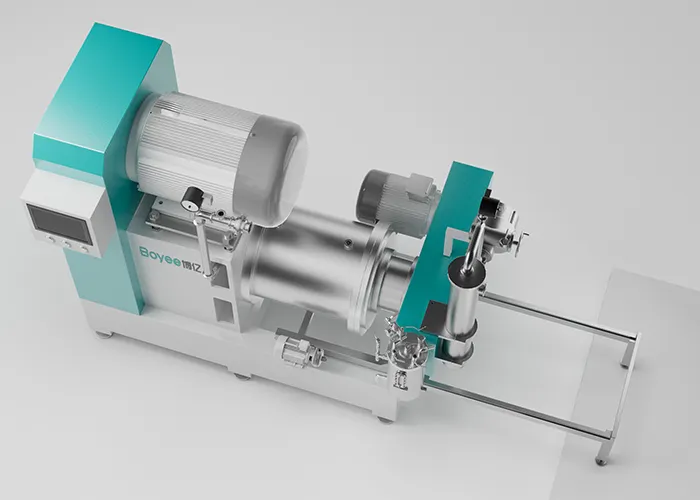

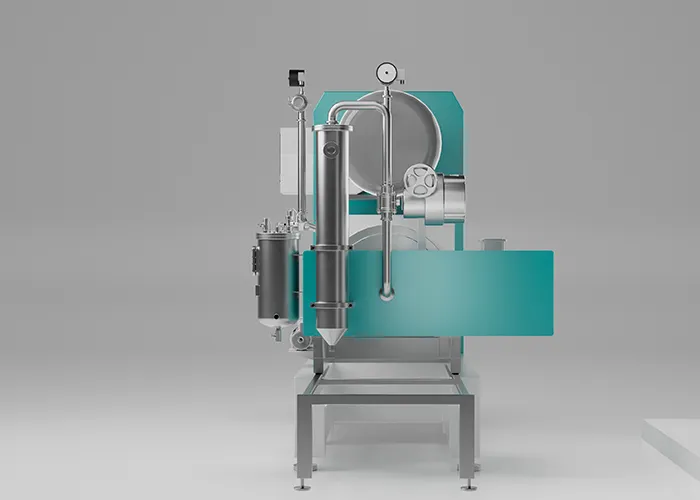

BOYEE Bead Mill for Cell Disruption

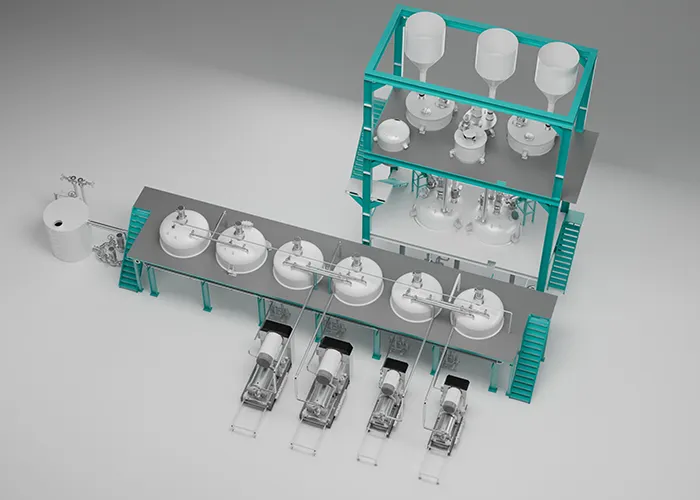

Product Display

Product Description

Material grinding and separation operate independently, Boyee TurboMax turbo or rod pin grinding structure for high grinding efficiency and narrow particle size distribution. Grinding chamber and structural parts can be selected for different materials, low wear, high efficiency.

Product Advantages

● Centrifugal separation of abrasive material, high stability without blocking material

● Material grinding and separation operate independently

● Finer grinding and dispersion effect

● Optional turbo and rod pin grinding systems

● Suitable for low viscosity materials

Product Parameters

| Model | Volume(L) | Power(kW) | Speed(r/min) | Media diameter(mm) | Weight(kg) | Size(mm) |

| LMM-3L | 3 | 7.5 | 0-1450 | 0.1-1 | 800 | 1400×1100×1680 |

| LMM-10L | 10 | 18.5 | 0-1460 | 0.05-1 | 1500 | 1800×1200×1550 |

| LMM-30L | 30 | 45 | 0-1000 | 0.05-1 | 2100 | 1800×1300×1800 |

| LMM-60L | 58 | 75 | 0-776 | 0.05-1 | 2800 | 3290×1478×1950 |

| LMM-90L | 98 | 75-90 | 0-776 | 0.05-1 | 3377 | 3290×1478×1950 |

| LMM-150L | 120-180 | 160 | 0-627 | 0.05-1 | 5600 | 4500×1700×2400 |

| LMM-400L | 400 | 315 | 0-927 | 0.05-1 | 8600 | 4600×1600×2400 |

Product Features

Material grinding and separation operate independently, Boyee TurboMax turbo or rod pin grinding structure for high grinding efficiency and narrow particle size distribution. Grinding chamber and structural parts can be selected for different materials, low wear, high efficiency.

Product Application

Faqs

A diaphragm pump is a type of positive displacement pump that uses a flexible diaphragm to transfer fluid. The pump consists of a chamber containing the diaphragm, an inlet valve, and an outlet valve. When the diaphragm is flexed, it creates a vacuum that draws fluid into the chamber through the inlet valve. When the diaphragm is released, it pushes the fluid out of the chamber through the outlet valve. The diaphragm separates the fluid being pumped from the moving parts of the pump, making it a reliable and versatile choice for a range of applications, including chemical processing, food and beverage production, and wastewater treatment. Diaphragm pumps can be operated using various power sources, including electric motors, air compressors, and hydraulic systems, and can handle a wide range of fluids, from water and oil to corrosive chemicals and slurries.

Diaphragm pumps are often used in applications that require a high degree of safety and reliability, as the diaphragm acts as a barrier between the pumped fluid and the environment.

They can be used to pump fluids at a range of pressures, from low to high, depending on the model and design of the pump.

Diaphragm pumps are available in different materials, including metal, plastic, and rubber, which allows them to handle a variety of corrosive, abrasive, or high-temperature fluids.

They are also available in different configurations, including single and double diaphragm pumps, which can affect the flow rate, pressure, and efficiency of the pump.

Diaphragm pumps are relatively easy to maintain and repair, as they have a simple design and few moving parts.

One potential disadvantage of diaphragm pumps is that they can be sensitive to dry running, which can damage the diaphragm or cause the pump to fail. Therefore, it is important to ensure that the pump is always primed and filled with fluid before operation.

Company Advantages

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD's bead mill for cell disruption emphasizes the value of innovation and design.

· The bead mill for cell disruption is very convenient and easy to handle for its high performance.

· The product has been widely recognized in the industry under the influence of BOYEE.

Company Features

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD has strengthened market dominance starting from the bead mill for cell disruption business to product solutions over the years.

· BOYEE (SHENZHEN) INDUSTRIAL TECHNOLOGY CO., LTD is especially prominent in terms of technological and scientific capacities.

· BOYEE is a brand which sticks to the customer first principle. Check it!

Application of the Product

Various in function and wide in application, the bead mill for cell disruption can be used in many industries and fields.

With Internet technology, we provide a one-stop solution for practical and effective implementation of related problems encountered in the process of purchasing products.

Saturday: 9:00AM~4:00 PM