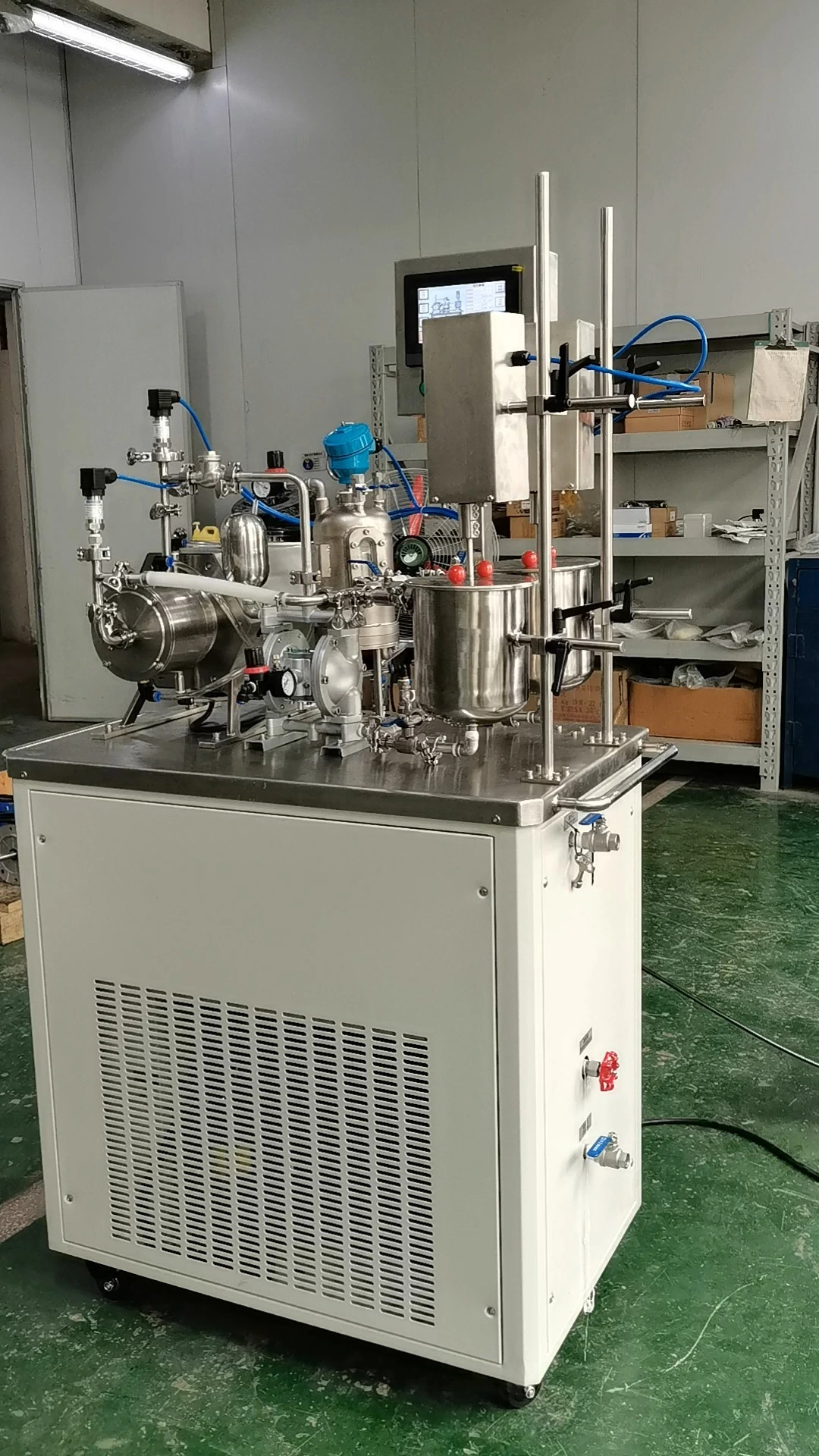

Boyee NMM Nano Laborataory Bead Mill 1L-2L Agitator Bead Mill

The first is the machine seal can, which has excellent cooling capacity to ensure the stability of the equipment during the working process. Pressure sensors and temperature sensors, which can measure and adjust the pressure and discharge temperature to ensure the accuracy of the experiment. The chiller maintains the stable operation of the equipment through the cooling system and provides sufficient cooling capacity. The main motor is the core component that drives the whole experimental machine, and its strong power ensures the efficient operation of the equipment.

The grinding chamber is an important part of the experimental machine, there are different materials (zirconia or silicon carbide), the rotor also has two structures, you can choose turbine and rod pin two structures. The turbine structure has a good dispersion effect, while the rod pin structure has a good crushing effect. In terms of material selection, different materials can be selected according to the experimental needs and the characteristics of different materials. Zirconia has excellent wear resistance and is suitable for grinding various materials; Polyurethane is flexible and suitable for grinding of materials with strong hardness.

Saturday: 9:00AM~4:00 PM