The Revolutionary Centrifugal Bead Mill: Revolutionizing Grinding Technology

Welcome to our article, where we delve into the fascinating realm of grinding technology revolutionized by the revolutionary centrifugal bead mill. If you are curious about the advancements in this field and how it is reshaping industries, we invite you to embark on this exciting journey with us. Explore the incredible capabilities and innovations of this groundbreaking mill that are poised to redefine the way we grind materials. Join us as we uncover the transformative potential of the centrifugal bead mill and its profound impact on various industries. Prepare to be amazed as we delve deeper into the intricacies of this impressive technology and its ability to enhance processes, efficiency, and quality. Are you ready to witness the future of grinding? Let's begin our exploration together.

Introduction to the Centrifugal Bead Mill: A Game-Changer in Grinding Technology

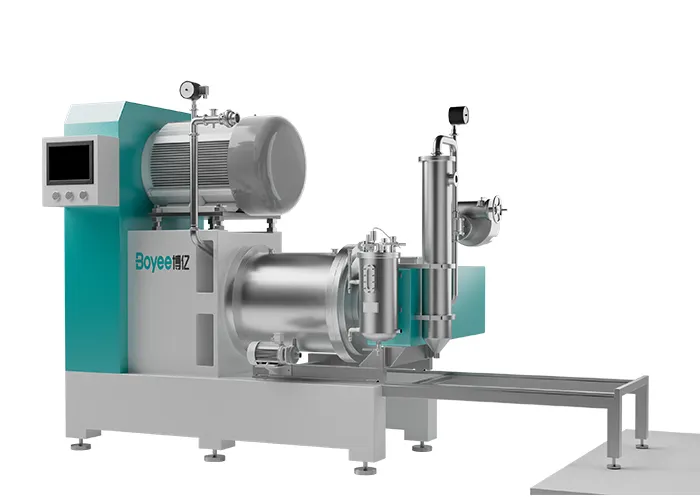

Grinding technology has seen significant advancements over the years, with various methods and machinery employed to obtain the desired particle size and consistency. Among the latest innovations in this field is the centrifugal bead mill, a game-changer that has already revolutionized grinding technology. Developed by BOYEE, a leading manufacturer in this space, the centrifugal bead mill offers unparalleled performance and efficiency, making it a sought-after solution in various industries.

The concept of the centrifugal bead mill revolves around the use of grinding beads that are accelerated by a high-speed rotor, creating a powerful centrifugal force. This force propels the beads outward, resulting in a highly efficient grinding process. Unlike traditional grinding mills that rely on gravity or shear forces alone, the centrifugal bead mill ensures even distribution of energy throughout the grinding chamber, ensuring consistent results every time.

One of the key benefits of the centrifugal bead mill is its ability to achieve sub-micron particle size reduction. The high-speed rotation of the rotor combined with the acceleration of the grinding beads enables the mill to break down materials into incredibly fine particles. This level of precision is particularly crucial in industries such as pharmaceuticals, where the particle size of drugs can have a significant impact on their efficacy.

Versatility is another hallmark feature of the centrifugal bead mill. It can handle a wide range of materials, including but not limited to pigments, paints, inks, ceramics, minerals, and chemicals. Its adaptability to various applications makes it a valuable tool for different manufacturing processes. Whether you need to produce nano-sized particles or simply achieve a consistent particle size distribution, the centrifugal bead mill offers a customizable solution.

BOYEE, a renowned name in the industry, has taken grinding technology to new heights with their centrifugal bead mill. Their expertise in engineering and innovation has led to the creation of a machine that surpasses industry standards in terms of performance and reliability. The BOYEE centrifugal bead mill boasts robust construction and a user-friendly design, ensuring smooth operation and longevity.

In addition to its technical prowess, the BOYEE centrifugal bead mill also brings cost-saving benefits to manufacturers. Its high-efficiency grinding process minimizes energy consumption, reducing operational costs. Furthermore, the mill's ability to achieve precise particle size distribution eliminates the need for additional processing steps, streamlining the production workflow.

Safety is of utmost importance in any manufacturing environment, and the centrifugal bead mill prioritizes this aspect. BOYEE has implemented advanced safety features in their mill, including interlocking mechanisms and emergency stop buttons. This ensures that operators can work with peace of mind, knowing that their well-being is protected.

In conclusion, the centrifugal bead mill has truly revolutionized grinding technology. Its ability to achieve sub-micron particle size reduction, versatility, and cost-saving benefits make it an indispensable tool for numerous industries. BOYEE, with their expertise and dedication to innovation, has established themselves as a leader in this field. With their centrifugal bead mill, manufacturers can expect unparalleled performance, efficiency, and safety. Embrace the future of grinding technology and experience the game-changing capabilities of the BOYEE centrifugal bead mill.

Understanding the Mechanism Behind the Centrifugal Bead Mill: How It Works

In recent years, the field of grinding technology has witnessed a groundbreaking advancement with the introduction of the centrifugal bead mill. This revolutionary equipment, also known as the BOYEE Centrifugal Bead Mill, has completely transformed the way grinding processes are carried out. In this article, we will delve into the intricate mechanism behind this cutting-edge technology and explore how it operates to deliver exceptional performance.

1. The Concept of Centrifugal Bead Mill:

The centrifugal bead mill is a state-of-the-art grinding tool that utilizes centrifugal force to separate the grinding media from the material being processed. Unlike conventional mills, which rely on the force of gravity to cause grinding media and particles to come into contact, the centrifugal bead mill induces intense motion within the mill chamber. This motion creates a unique grinding mechanism that achieves highly efficient and uniform particle size reduction.

2. How Does the Centrifugal Bead Mill Work?

The BOYEE Centrifugal Bead Mill operates through a series of controlled mechanical and fluid dynamics. Let's explore the key components and their functions:

a. Rotor and Stator:

At the heart of the centrifugal bead mill is the rotor, which spins at high speeds, creating centrifugal force. The rotor is equipped with a series of highly wear-resistant pins or discs that accelerate the grinding media. The stator, on the other hand, remains stationary and is responsible for containing the material being processed.

b. Grinding Media:

The centrifugal bead mill employs small spherical beads, typically made of Zirconium oxide or yttrium-stabilized Zirconia, as the grinding media. These beads are carefully selected based on their size, density, and hardness to ensure optimal performance and minimal wear.

c. Cooling System:

To maintain the desired temperature during the grinding process, the centrifugal bead mill incorporates an efficient cooling system. This prevents overheating and ensures the preservation of the material properties.

d. Material Feed and Discharge:

The material to be processed is introduced into the milling chamber through a specially designed feed system. As the material interacts with the rapidly spinning grinding media, it undergoes continuous size reduction and particle dispersion. The final product is then discharged through an outlet, ready for further processing or use.

3. Advantages of the BOYEE Centrifugal Bead Mill:

The BOYEE Centrifugal Bead Mill offers numerous advantages over traditional grinding methods:

a. Improved Efficiency:

The centrifugal bead mill operates at higher rotational speeds, allowing for shorter residence times and faster processing. This leads to increased productivity and reduced energy consumption.

b. Narrow Particle Size Distribution:

By harnessing the power of centrifugal force, the bead mill creates intense collisions and shear forces, resulting in a narrow and consistent particle size distribution. This makes it exceptionally useful in applications that require precise control over particle size.

c. Superior Grinding Performance:

The BOYEE Centrifugal Bead Mill excels at grinding difficult-to-disperse materials and achieves remarkable results even with highly viscous slurries. It effectively reduces particle size to submicron levels, creating finely dispersed and uniform products.

In conclusion, the BOYEE Centrifugal Bead Mill stands as a revolutionary advancement in grinding technology. Through its unique mechanism, it offers improved efficiency, narrow particle size distribution, and superior grinding performance. With its ability to handle a wide range of materials, this innovative equipment paves the way for enhanced product quality and process optimization. Experience the future of grinding technology with the BOYEE Centrifugal Bead Mill and propel your business to new heights of success.

Advantages and Benefits of Using the Centrifugal Bead Mill in Grinding Processes

Introducing the Revolutionary Centrifugal Bead Mill: Revolutionizing Grinding Technology

Grinding processes play a crucial role in various industries, ranging from pharmaceuticals and cosmetics to paint and ink manufacturing. As the demand for finer particle sizes and superior quality products increases, traditional grinding techniques often fall short in providing the desired outcomes. However, the introduction of the centrifugal bead mill has sparked a revolutionary change in grinding technology, allowing manufacturers to achieve significant advantages and reap numerous benefits.

What is a Centrifugal Bead Mill?

A centrifugal bead mill, also known as a sand mill or media mill, is a grinding machine that uses abrasive beads to grind or disperse solid materials. Unlike traditional ball mills, which rely on impact and abrasion, this cutting-edge mill operates on the principle of centrifugal force. As the rotating rotor accelerates the grinding media, the materials are subjected to intense shear and collision forces, resulting in rapid and efficient particle size reduction.

Advantages of the Centrifugal Bead Mill:

1. Superior Particle Size Distribution: The centrifugal bead mill offers exceptional control over particle size distribution, ensuring consistent and uniform grinding results. With the ability to produce finer particle sizes, manufacturers can enhance the quality and performance of their products.

2. Increased Production Efficiency: By harnessing the power of centrifugal force, the bead mill allows for high-speed grinding, significantly reducing processing time. This leads to increased productivity, shorter manufacturing cycles, and ultimately, cost savings for businesses.

3. Enhanced Energy Efficiency: The centrifugal bead mill consumes less energy compared to other grinding methods, making it a more sustainable choice. By minimizing energy waste, manufacturers can achieve a greener and more environmentally friendly production process.

4. Versatility in Grinding Applications: The centrifugal bead mill is incredibly versatile and can be used for a wide range of grinding applications. Whether it's grinding pigments for paints or producing fine powders for pharmaceutical formulations, this revolutionary technology can meet the diverse needs of various industries.

Benefits of Choosing BOYEE's Centrifugal Bead Mills:

1. Unparalleled Quality and Reliability: BOYEE, a trusted name in the industry, offers high-quality centrifugal bead mills that are built to last. With a focus on performance and durability, BOYEE's machines ensure long-term reliability and consistent results, providing unparalleled value for businesses.

2. Customized Solutions: BOYEE understands that every customer has unique requirements. With a team of experienced engineers, the company provides tailored solutions based on specific grinding needs, ensuring the best possible outcomes for each application.

3. Cutting-Edge Technology: As a leader in grinding technology, BOYEE continuously innovates and incorporates the latest advancements into its centrifugal bead mills. By leveraging state-of-the-art features and functionalities, BOYEE's machines deliver optimal performance and efficiency, setting new industry standards.

4. Expert Technical Support: BOYEE believes in building strong relationships with its customers by offering comprehensive technical support. Whether it's installation assistance, troubleshooting guidance, or maintenance services, BOYEE's team of experts is always ready to provide timely and professional assistance.

In conclusion, the centrifugal bead mill has revolutionized grinding technology, providing manufacturers with numerous advantages and benefits. With its ability to produce superior particle size distribution, increase production efficiency, enhance energy efficiency, and offer versatility in grinding applications, this cutting-edge technology is transforming various industries. When it comes to choosing a centrifugal bead mill, BOYEE stands as a reliable and reputable brand, offering unmatched quality, customized solutions, and cutting-edge technology, along with expert technical support. Embrace the revolutionary power of centrifugal bead mills and take your grinding processes to new heights with BOYEE.

Applications of the Revolutionary Centrifugal Bead Mill: Unlocking New Possibilities

Grinding technology has long been a crucial aspect of various industries, contributing to the production of fine particles and achieving desired particle sizes. However, traditional grinding methods have often been plagued by limitations such as low efficiency, high energy consumption, and limited control over particle size distribution. Fortunately, a breakthrough has arrived in the form of the revolutionary centrifugal bead mill, offering a new level of grinding technology that is set to transform numerous industries. In this article, we will explore the vast applications of the centrifugal bead mill and how it is unlocking new possibilities across different sectors.

The centrifugal bead mill, developed and manufactured by BOYEE, is an innovative grinding machine that utilizes centrifugal force and beads to achieve superior particle size reduction. Unlike traditional grinding mills, the centrifugal bead mill operates at significantly higher speeds, allowing for faster processing and finer particle sizes. This technology has been hailed as a game-changer in the field of grinding, with its potential to overcome the limitations of conventional methods.

One of the primary applications of the centrifugal bead mill is in the paint and pigment industry. Achieving the desired color intensity and dispersion in paints and pigments is a critical factor for manufacturers, and the centrifugal bead mill offers a solution that meets these requirements. By efficiently grinding and dispersing pigments, the bead mill ensures a homogenous mixture, resulting in vibrant and high-quality paint finishes. Additionally, the advanced control options of the centrifugal bead mill allow for precise adjustments, enabling manufacturers to achieve specific particle size distributions for different applications.

Another industry that greatly benefits from the centrifugal bead mill is the pharmaceutical sector. The production of pharmaceutical powders requires precise particle size control to ensure optimal drug efficacy. With its ability to achieve sub-micron particle sizes, the bead mill offers pharmaceutical companies an invaluable tool for enhancing drug performance. The centrifugal bead mill also enables the processing of heat-sensitive pharmaceutical materials without compromising their integrity, making it a versatile solution for a wide range of pharmaceutical applications.

The food and beverage industry is another sector that can harness the potential of the centrifugal bead mill. From grinding spices to processing cocoa beans, this grinding technology provides precise control over particle size distribution, resulting in enhanced flavors and textures. The centrifugal bead mill's high-speed operation and efficient grinding capabilities make it a suitable choice for food manufacturers seeking to improve product quality and consistency.

Moreover, the centrifugal bead mill finds application in the manufacturing of advanced materials, such as ceramics, composites, and nano-materials. The ability to finely grind and disperse particles allows for the production of materials with improved properties, such as increased strength, enhanced conductivity, and tailored surface functionalities. This opens up new avenues for materials engineering and enables the development of innovative products across various industries.

In conclusion, the revolutionary centrifugal bead mill, brought to you by BOYEE, is transforming the world of grinding technology. Its wide range of applications spans industries such as paints and pigments, pharmaceuticals, food and beverages, and materials manufacturing. By harnessing the power of centrifugal force and beads, this groundbreaking technology offers unprecedented control over particle size distribution, resulting in superior product quality and performance. As the industry evolves, the centrifugal bead mill continues to unlock new possibilities, driving innovation and pushing the boundaries of what is achievable in the realm of grinding technology.

Future Prospects and Innovations in Centrifugal Bead Mill Technology: Continuing the Revolution

Grinding technology has come a long way over the years, and one of the most ground-breaking advancements in this field is the development of the centrifugal bead mill. This article explores the future prospects and innovations in this technology, specifically focusing on the revolutionary impact it has had on the industry. With BOYEE at the forefront of this innovation, let's delve into the world of centrifugal bead mills.

1. Understanding the Centrifugal Bead Mill:

At its core, a centrifugal bead mill is a highly efficient grinding machine that utilizes centrifugal force to disperse and grind materials. Unlike conventional milling methods, where grinding media is stationary, the centrifugal bead mill creates a dynamic and high-energy grinding environment. This allows for faster, more efficient, and uniform particle size reduction across a wide range of materials.

2. Unveiling the Future Prospects:

The future prospects for centrifugal bead mill technology are vast, as this innovative solution continues to revolutionize the grinding industry. The versatility and adaptability of centrifugal bead mills have unlocked new opportunities in various sectors. Its potential applications span across industries such as pharmaceuticals, paints, coatings, inks, electronics, and many more.

a. Pharmaceutical Industry:

In the pharmaceutical industry, the precise and controlled size reduction achieved by centrifugal bead mills is crucial for improving drug formulation and bioavailability. The ability to grind and disperse active pharmaceutical ingredients (APIs) with high efficiency ensures optimal drug performance and enhances patient outcomes.

b. Paints and Coatings Industry:

Centrifugal bead mills have transformed the paints and coatings industry by facilitating the production of high-quality and consistent dispersions. With enhanced dispersion stability, pigments, fillers, and additives can be uniformly distributed, resulting in superior color strength, gloss, and durability of the final product.

c. Ink Industry:

Inks play a vital role in numerous applications, including printing and packaging. The technological advancements in centrifugal bead mill technology have led to the development of high-performance ink formulations. Improved particle size distribution and dispersion ensure vibrant colors, optimal ink flow, and print quality.

d. Electronics Industry:

The electronics industry requires precise dispersion of conductive and non-conductive materials for the production of electronic inks, adhesives, and coatings. Centrifugal bead mills provide the necessary grinding and dispersion solutions for achieving consistent electronic materials with high conductivity and reliability.

3. BOYEE: Pioneering the Revolution:

BOYEE, a leading brand in centrifugal bead mill technology, has been instrumental in pushing the boundaries of innovation. With years of expertise and research, BOYEE has consistently introduced groundbreaking advancements in grinding technology.

a. Enhanced Grinding Performance:

BOYEE's centrifugal bead mills incorporate state-of-the-art features, such as advanced rotor designs, adjustable milling chambers, and efficient cooling systems. These advancements ensure superior grinding performance, higher throughput, and reduced energy consumption.

b. Smart Digital Control:

BOYEE integrates smart digital control systems into their centrifugal bead mills, allowing for precise and automated operation. With easy-to-use interfaces and real-time monitoring capabilities, operators can achieve optimal results while maintaining process control and consistency.

c. Customizable Solutions:

BOYEE understands the diverse needs of different industries and offers customizable centrifugal bead mill solutions. By tailoring their equipment to specific requirements, BOYEE ensures maximum efficiency, productivity, and cost-effectiveness for their customers.

The centrifugal bead mill technology has truly revolutionized the field of grinding. BOYEE's unwavering commitment to innovation and continuous advancements has propelled this industry forward. With its future prospects expanding across various sectors, the centrifugal bead mill is set to transform the way materials are ground and dispersed, offering immense potential for improved quality, efficiency, and performance.

Conclusion

In conclusion, the revolutionary centrifugal bead mill has undoubtedly transformed the world of grinding technology. With its innovative design and efficient functionality, it has paved the way for a more streamlined and precise grinding process. As a company with 19 years of experience in the industry, we have witnessed firsthand the immense impact this technology has had on various sectors. From improving production efficiency to enhancing the quality of final products, the centrifugal bead mill has revolutionized the way we approach grinding. We are proud to have been a part of this journey and look forward to further advancements in this field. As the industry continues to evolve, we remain committed to providing unparalleled expertise and top-notch equipment to meet the ever-growing demands of our customers. Together, let us continue to push the boundaries of grinding technology and unlock limitless possibilities in the manufacturing world.

Saturday: 9:00AM~4:00 PM