Beads Mill: Unveiling The Revolutionary Technology Shaking Up The Manufacturing Industry

Welcome to our article, where we delve into the realm of manufacturing innovation and introduce you to the groundbreaking technology that is shaking up the industry: Beads Mill. In this fast-paced world, it is essential to stay ahead of the game, and Beads Mill promises nothing short of a revolutionary transformation. Join us as we explore its profound impact, uncovering how this cutting-edge technology is redefining manufacturing processes, streamlining production, and unlocking untapped potentials. Prepare to be captivated as we unveil the game-changing advancements that are setting the stage for a dynamic future in the manufacturing realm. Continue reading to discover the endless possibilities that Beads Mill brings to the table and embrace the exciting journey of innovation that lies ahead.

Introduction to Beads Mill: A Groundbreaking Technology Disrupting Manufacturing Processes

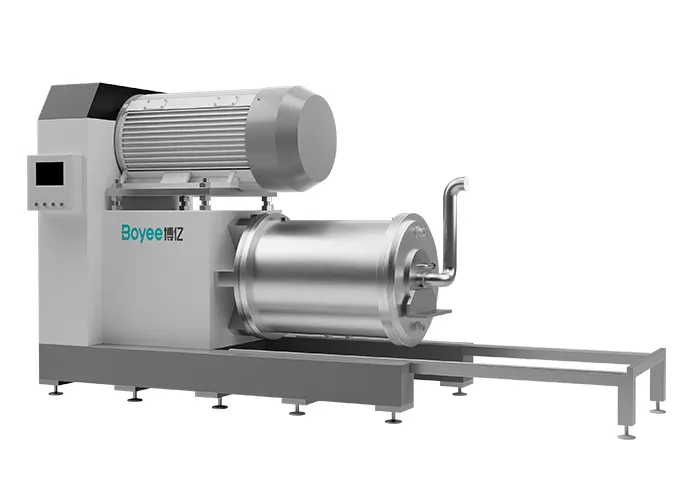

The manufacturing industry is at the forefront of technological advancements that are constantly shaping the way products are designed, developed, and produced. One such groundbreaking technology that is revolutionizing the manufacturing industry is the Beads Mill. Developed by BOYEE, the Beads Mill introduces a new and highly efficient method of manufacturing, challenging traditional processes and paving the way for increased productivity, reduced costs, and improved product quality.

The Beads Mill technology is an innovative approach that utilizes tiny beads to grind materials into nanoparticles. This process allows for precise control over particle size, shape, and distribution, resulting in superior materials with enhanced properties. Additionally, the Beads Mill can handle a wide range of materials, including metals, ceramics, polymers, and composites, making it incredibly versatile for various applications across industries.

One of the key advantages of the Beads Mill is its ability to reduce manufacturing time significantly. Traditional manufacturing methods often involve multiple steps, such as milling, grinding, and polishing, which can be time-consuming and expensive. With the Beads Mill, these processes are streamlined into a single operation, reducing production time and increasing overall efficiency.

Furthermore, the Beads Mill ensures consistent quality and uniformity in the produced materials. By controlling the size and shape of the nanoparticles, manufacturers can achieve precise control over the properties of the final product. This level of control is particularly beneficial in industries such as healthcare, where the performance and reliability of medical devices and pharmaceutical products are of utmost importance.

The Beads Mill also has the potential to reduce manufacturing costs significantly. By eliminating the need for multiple processing steps and minimizing material waste, manufacturers can achieve substantial cost savings. Moreover, the Beads Mill consumes less energy compared to traditional manufacturing processes, making it an eco-friendly alternative that reduces carbon emissions and environmental impact.

BOYEE, the pioneering company behind the Beads Mill technology, has been at the forefront of innovation in the manufacturing industry for over a decade. With a strong commitment to research and development, BOYEE has continuously pushed boundaries and introduced disruptive technologies that transform industries.

To showcase the capabilities of the Beads Mill, BOYEE has collaborated with various industries, including aerospace, automotive, electronics, and healthcare, to develop groundbreaking products and materials. From lightweight and high-strength alloys for aerospace applications to advanced electronic components with enhanced performance, the Beads Mill has proven its potential to revolutionize manufacturing processes across diverse sectors.

In conclusion, the introduction of the Beads Mill technology marks a significant milestone in the manufacturing industry. Its ability to produce materials with precise control over properties, reduce manufacturing time and costs, and enhance overall product quality positions it as a game-changer in the field. As BOYEE continues to innovate and expand the capabilities of the Beads Mill, we can expect even greater disruptions and advancements in manufacturing processes, setting new standards for the industry as a whole.

The Advantages and Impact of Beads Mill on the Manufacturing Industry

In today's fast-paced manufacturing world, innovation and technological advancements are key to staying ahead of the competition. One such groundbreaking technological development is the beads mill. This state-of-the-art equipment is revolutionizing the manufacturing industry, offering numerous advantages and leaving a lasting impact.

What exactly is a beads mill? Essentially, it is a grinding machine that utilizes small beads made of various materials, such as glass, ceramic, or steel, to disintegrate or reduce the size of particles within a liquid medium. The unique design of the beads mill increases the efficiency and effectiveness of the grinding process, leading to immense benefits for manufacturers.

One of the foremost advantages of using a beads mill is its ability to achieve particle size reduction with remarkable precision. By carefully selecting the size, shape, and material of the beads, manufacturers can control the final particle size of their products with high accuracy. This level of control guarantees consistent quality and uniformity, a crucial element in manufacturing processes across industries.

In addition to precise particle size reduction, the beads mill offers exceptional grinding efficiency. The grinding beads, continuously agitated within the mill, provide a high-energy impact, resulting in faster and more efficient grinding. This translates into shorter processing times and increased productivity for manufacturers, enabling them to meet growing demand without compromising on product quality.

Furthermore, the beads mill offers versatility in terms of the range of materials it can effectively grind. From pigments, dyes, and paints to pharmaceuticals, cosmetics, and even food products, this technology is adaptable to various industries. The ability to grind a wide array of materials makes the beads mill an invaluable asset for manufacturers looking to expand their product lines or explore new markets.

The impact of the beads mill on the manufacturing industry is truly transformative. As mentioned earlier, its ability to provide consistent quality and uniform particle size plays a significant role in enhancing product performance. This, in turn, leads to customer satisfaction and loyalty, ultimately driving business growth.

A prime example of the beads mill's impact can be seen in the paint and coatings industry. By achieving consistent particle size reduction, paint manufacturers can ensure the even dispersion of pigments, resulting in vibrant and aesthetically pleasing colors. The beads mill's efficiency also enables manufacturers to rapidly produce large quantities of paint, meeting market demands promptly and effectively.

In the pharmaceutical industry, the beads mill offers substantial advantages in terms of drug development and formulation. The precise particle size reduction achieved through this technology allows for better control over drug release and absorption, ultimately improving the effectiveness of medications. Additionally, the beads mill enables the production of nanoparticles, opening up new possibilities in drug delivery systems and biomedical applications.

As the demand for sustainable manufacturing practices continues to grow, the beads mill emerges as a valuable tool. The grinding process within this technology produces minimal heat, reducing energy consumption and minimizing the impact on the environment. Manufacturers embracing the beads mill not only benefit from its efficiency but also contribute to a more sustainable future.

In conclusion, the beads mill is a revolutionary technology that is visibly shaking up the manufacturing industry. Its ability to provide precise particle size reduction, exceptional grinding efficiency, and versatility in materials makes it an indispensable asset for manufacturers across various sectors. The lasting impact of the beads mill includes enhanced product quality, increased productivity, and the potential for innovation and sustainability. With its numerous advantages, it is clear why the beads mill, under the brand name BOYEE, is rapidly gaining popularity and transforming the manufacturing landscape.

How Beads Mill Works: Understanding the Revolutionary Technology Behind It

In the ever-evolving world of manufacturing, advancements in technology continually reshape the landscape. A key player in this revolution is the beads mill, a cutting-edge technology that has captured the attention of industry professionals worldwide. This article will delve into the inner workings of beads mill and shed light on how it is transforming the manufacturing industry.

Understanding Beads Mill:

At its core, beads mill is a revolutionary technology employed in various manufacturing processes. It harnesses the power of tiny beads, typically made of materials such as glass, ceramic, or steel, to grind and disperse particles. Unlike traditional milling methods, which rely on large equipment and excessive energy consumption, beads mills offer a compact and energy-efficient alternative.

The Working Principle:

Beads mills employ a simple yet ingenious working principle that distinguishes them from other milling technologies. In a beads mill, the tiny beads are placed within a cylindrical chamber, often referred to as a grinding vessel. A mixture of solid particles and liquid, known as the slurry, is introduced into the chamber.

Next, the beads are set into motion by a rotating shaft equipped with various agitators. As the beads collide with the particles in the slurry, they exert enough force to break down the solid components into smaller fragments. This process, commonly known as grinding or dispersion, results in the creation of a homogeneous mixture.

Applications and Advantages:

The beads mill technology presents a wide array of applications across industries. It has proven particularly valuable in industries such as pharmaceuticals, cosmetics, paints and coatings, and food processing. By utilizing beads mills, manufacturers can achieve superior particle size reduction, improved material dispersion, and enhanced product quality.

One of the notable advantages of beads mills is their versatility. These mills can handle both wet and dry milling processes, making them highly adaptable to diverse manufacturing needs. Additionally, beads mills offer precise control over particle size distribution, enabling manufacturers to produce products with consistent quality.

BOYEE's Role in Advancing Beads Mill Technology:

BOYEE, a leading manufacturer in the field of milling equipment, has been at the forefront of harnessing the potential of beads mills. With their innovative approach and commitment to research and development, BOYEE has successfully introduced several groundbreaking beads mill models to the market.

BOYEE's beads mills incorporate cutting-edge features that enhance productivity and efficiency. Their state-of-the-art designs prioritize user-friendly operation and maintenance, enabling manufacturers to optimize their manufacturing processes. With BOYEE beads mills, manufacturers benefit from improved energy efficiency, reduced processing time, and exceptional product quality.

As the manufacturing industry continues to embrace technological advancements, the beads mill stands as a shining example of revolutionary innovation. Its ability to achieve efficient particle size reduction and homogenous material dispersion has made it an indispensable tool across various industries.

With BOYEE's dedication to advancing beads mill technology, manufacturers can expect to witness even more significant improvements in efficiency, productivity, and product quality. As we move forward, embracing technologies like beads mills will undoubtedly redefine the manufacturing industry and pave the way for a more sustainable and profitable future.

Applications and Industries Benefiting from Beads Mill's Innovation

With the rapid advancements in technology, the manufacturing industry is experiencing a significant transformation. Among the groundbreaking developments, Beads Mill technology has emerged as a game-changer, revolutionizing various applications and industries worldwide. Developed by the industry-leading brand BOYEE, Beads Mill is a cutting-edge innovation that offers unparalleled efficiency and precision in manufacturing processes.

Used in an array of industries, Beads Mill has proven to be a versatile technology that contributes to enhanced productivity, reduced costs, and improved product quality. This article delves into the applications and industries that benefit from the innovative Beads Mill technology, shedding light on its wide-reaching impact.

1. Pharmaceutical Industry:

In the pharmaceutical industry, Beads Mill technology has revolutionized drug production. One of its key applications is in the formulation of oral solid dosage forms. The ability of Beads Mill to reduce particle size while maintaining uniformity is crucial in ensuring effective drug delivery and absorption. Additionally, this technology enables the production of complex drug formulations, contributing to advancements in personalized medicine.

2. Cosmetics Industry:

The cosmetics industry has also embraced Beads Mill technology, as it allows for the efficient production of high-quality cosmetic products. Beads Mill facilitates the dispersion and homogenization of various ingredients, resulting in improved texture, stability, and performance of cosmetic formulations. This technology has accelerated the development of new and innovative cosmetic products, meeting the ever-changing demands of consumers.

3. Food and Beverage Industry:

The food and beverage industry has discovered the numerous benefits of Beads Mill technology in various applications. From the production of beverages to the creation of stable emulsions, Beads Mill ensures uniform particle size distribution and enhanced flavor release. Furthermore, this technology enables the effective extraction of bioactive compounds from natural ingredients, leading to the development of functional food products.

4. Paints and Coatings Industry:

In the paints and coatings industry, Beads Mill technology has emerged as a key player in improving the efficiency and quality of manufacturing processes. This technology facilitates the dispersion of pigments and additives, resulting in highly stable and vibrant color formulations. Additionally, Beads Mill allows for the production of coatings with improved wear resistance and durability, meeting the demanding requirements of various industries.

5. Chemical Industry:

The chemical industry extensively benefits from the innovative Beads Mill technology in various applications. From the production of specialty chemicals to the refinement of raw materials, Beads Mill ensures precise control over particle size distribution and homogeneity. This technology facilitates the optimization of chemical reactions, reducing reaction times and enhancing product yield. Additionally, Beads Mill enables the production of nanomaterials with enhanced properties, expanding the possibilities in materials science.

The applications and industries benefiting from Beads Mill's innovation are vast and diverse. With its ability to enhance productivity, improve product quality, and reduce costs, this revolutionary technology has found its place in various sectors. As the leading brand in Beads Mill technology, BOYEE continues to push the boundaries of innovation, driving the manufacturing industry forward into a new era of efficiency and precision.

Future Prospects and Implications of Beads Mill for the Manufacturing Sector

The manufacturing industry has always been at the forefront of innovation and technological advancements. In recent years, a revolutionary technology known as beads mill has emerged, shaking up the manufacturing sector like never before. With the potential to revolutionize the way various materials are processed and manufactured, the future prospects and implications of beads mill are nothing short of exciting.

Beads mill, as the name suggests, utilizes tiny beads to grind and disperse materials. It is a high-energy, low-impact milling process that offers several advantages over traditional manufacturing methods. By utilizing the kinetic energy generated by the beads' collisions, beads mill can achieve finer and more precise particle size reduction, resulting in improved material quality and performance.

One of the key benefits of beads mill is its versatility. It can be used for a wide range of materials, including chemicals, pharmaceuticals, pigments, and even food products. This versatility makes it an attractive option for various industries, from pharmaceutical manufacturing to food processing. By using beads mill, manufacturers can achieve better control over the particle size distribution, leading to enhanced product consistency and quality.

Additionally, beads mill offers enhanced efficiency compared to traditional manufacturing processes. The high-energy collisions between the beads and the material being processed lead to faster and more efficient grinding, reducing processing time and increasing productivity. This not only improves the overall production capacity but also lowers manufacturing costs, making beads mill a cost-effective solution for manufacturers.

Another significant advantage of beads mill is its ability to work with small sample sizes. Traditional manufacturing processes often require large quantities of materials to be processed at once. This can be a challenge, especially for research and development purposes or when working with limited resources. Beads mill overcomes this limitation by allowing manufacturers to process smaller sample sizes, enabling them to test and develop new products on a smaller scale before scaling up for mass production. This not only saves time and resources but also promotes innovation and experimentation within the manufacturing sector.

The future prospects of beads mill are highly promising. As industries continue to evolve and demand more advanced manufacturing solutions, beads mill is poised to play a significant role in driving innovation and efficiency. The technology has already gained traction in various sectors, with numerous manufacturers adopting beads mill in their production processes.

For BOYEE, a leading provider of beads mill technology, the future looks bright. With a strong reputation for delivering innovative and high-quality products, BOYEE is well-positioned to capitalize on the growing demand for beads mill in the manufacturing industry. By continuously improving their technology and offering tailored solutions to different sectors, BOYEE aims to be at the forefront of the beads mill revolution, enabling manufacturers to unlock new possibilities and achieve unprecedented levels of productivity.

In conclusion, the revolutionary technology of beads mill is set to transform the manufacturing industry. With its numerous advantages, including enhanced control, efficiency, and versatility, beads mill offers a promising future for manufacturers across various sectors. For BOYEE, the future of beads mill looks bright, as they strive to be the leading provider of this groundbreaking technology. As industries continue to evolve, beads mill is poised to be at the forefront, shaking up the manufacturing sector and unlocking new possibilities for innovation and productivity.

Conclusion

In conclusion, the advent of Beads Mill technology has truly revolutionized the manufacturing industry, propelling it into a new era of efficiency, precision, and cost-effectiveness. With our 19 years of experience in the industry, we have witnessed first-hand the transformative impact of this groundbreaking technology. From increasing productivity to streamlining processes, Beads Mill has proven to be a game-changer for manufacturers worldwide. As we look towards the future, we are excited to continue driving innovation and pushing the boundaries of what is possible in the manufacturing sector. With Beads Mill at our disposal, we can confidently say that the future of manufacturing is brighter than ever before.

Saturday: 9:00AM~4:00 PM